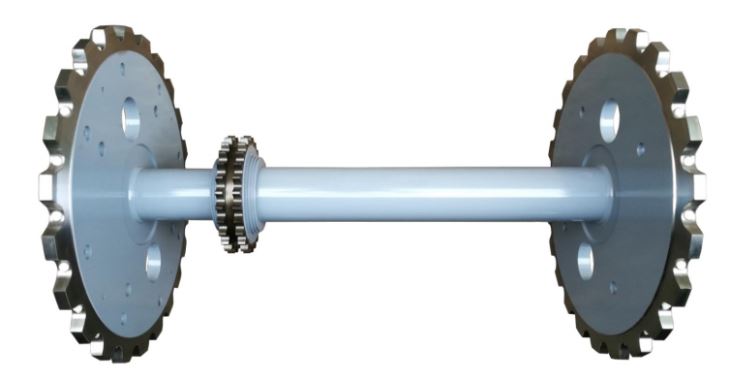

When it comes to the smooth and reliable operation of escalators, the Escalator Chains play a pivotal role. These chains are engineered to transmit motion and support the steps, ensuring passenger safety and comfort. As a critical component, they must meet stringent standards for durability, strength, and performance. In this comprehensive guide, we delve into the details of escalator chains, covering their specifications, parameters, and common queries to help you make informed decisions.

Escalator chains are designed with precision to handle heavy loads and continuous operation. Below are the essential parameters that define their quality and suitability for various applications.

For a clearer comparison, here is a table outlining standard escalator chain models and their specifications:

| Model | Pitch (mm) | Breaking Load (kN) | Weight (kg/m) | Material | Application |

|---|---|---|---|---|---|

| EC-100 | 100 | 180 | 15 | Alloy Steel | Light-duty escalators |

| EC-115 | 115 | 220 | 18 | Stainless Steel | Medium-duty commercial use |

| EC-133 | 133 | 300 | 25 | Heat-Treated Alloy | Heavy-duty public transport |

What are the primary functions of escalator chains in an escalator system?

Escalator chains serve to drive the steps, transmitting power from the motor to ensure synchronized movement. They also bear the weight of passengers and steps, maintaining stability and safety throughout operation. Properly designed chains reduce vibration and noise, contributing to a smoother ride.

How often should escalator chains be inspected and maintained?

Regular inspections are recommended every 3 to 6 months, depending on usage intensity. Maintenance includes checking for wear, tension adjustments, and lubrication. In high-traffic areas, more frequent checks may be necessary to prevent failures and extend the chain's lifespan, which typically ranges from 5 to 15 years with proper care.

What factors influence the choice of escalator chain material?

Material selection depends on environmental conditions, load requirements, and corrosion risks. Alloy steel is common for indoor use due to its strength, while stainless steel is preferred for outdoor or humid environments to resist rust. Heat treatment can enhance durability, making it suitable for heavy-duty applications.

Can escalator chains be customized for specific escalator models?

Yes, escalator chains can be tailored to fit various escalator designs, including different pitch sizes, lengths, and attachment configurations. Customization ensures compatibility with existing systems and optimizes performance based on specific operational demands, such as speed or load capacity.

What are the signs of wear or failure in escalator chains?

Common indicators include unusual noises (e.g., grinding or clicking), visible elongation beyond 2% of the original length, rust formation, and misalignment of steps. Regular monitoring helps detect early signs, allowing for timely replacements to avoid escalator downtime and safety hazards.

How does lubrication affect the performance of escalator chains?

Proper lubrication reduces friction between chain links, minimizing wear and energy consumption. It also helps prevent corrosion and noise. Using manufacturer-recommended lubricants at specified intervals ensures optimal performance and can extend the chain's service life by up to 20%.

Are there international standards for escalator chain manufacturing?

Yes, escalator chains must comply with standards such as ISO 4348 for chain dimensions and safety, EN 115 for escalator safety requirements, and ASME A17.1 for performance benchmarks. These standards ensure quality, reliability, and interoperability with global escalator systems.

What is the typical lead time for ordering and installing new escalator chains?

Lead times vary based on customization and stock availability, but standard orders通常 take 4-8 weeks for production and delivery. Installation by certified technicians may add 1-2 weeks, depending on the complexity of the escalator system and site conditions.