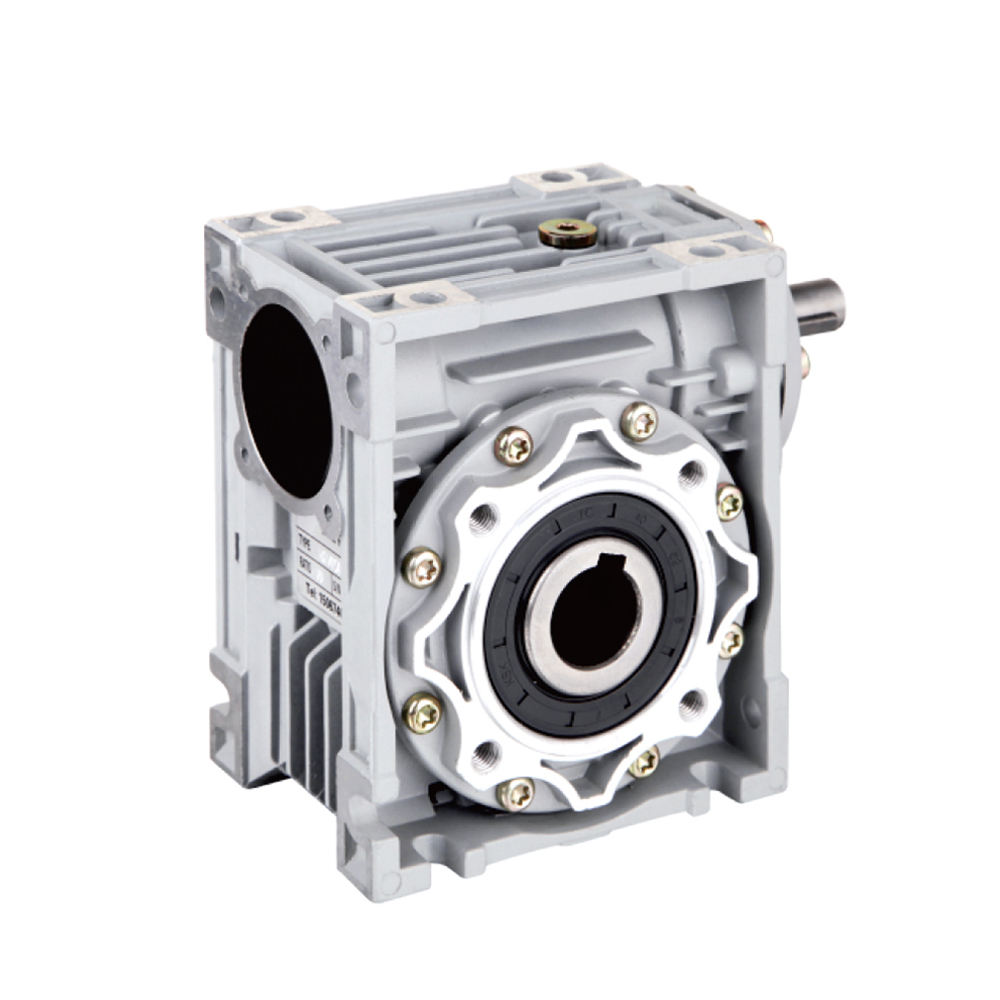

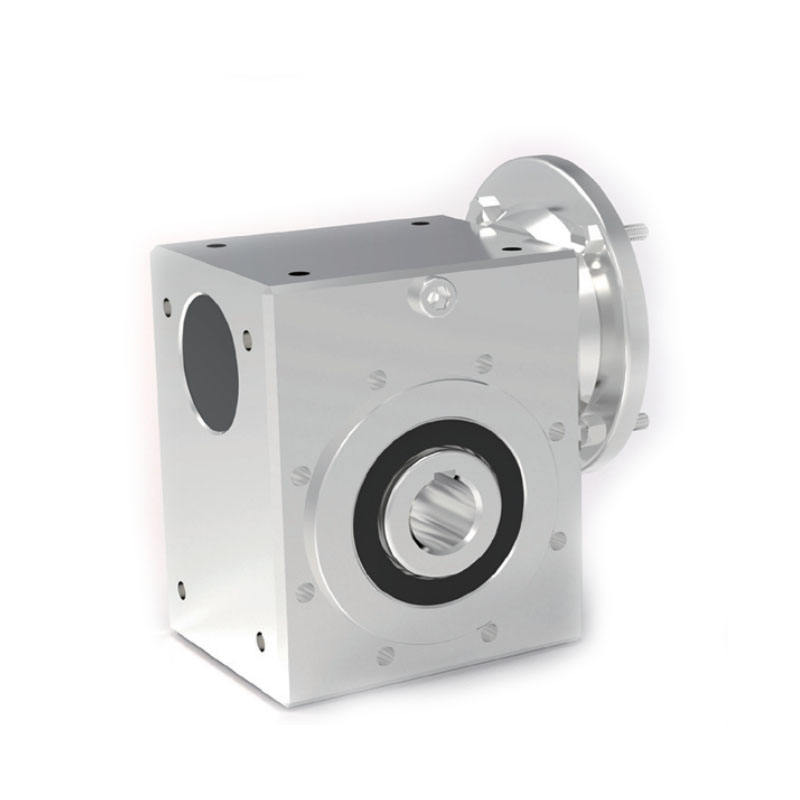

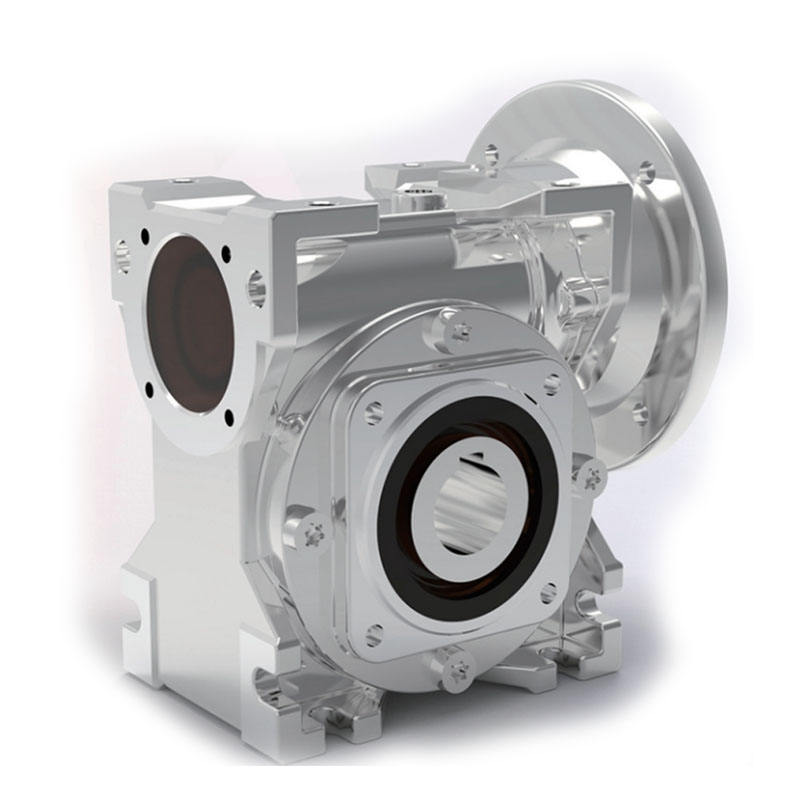

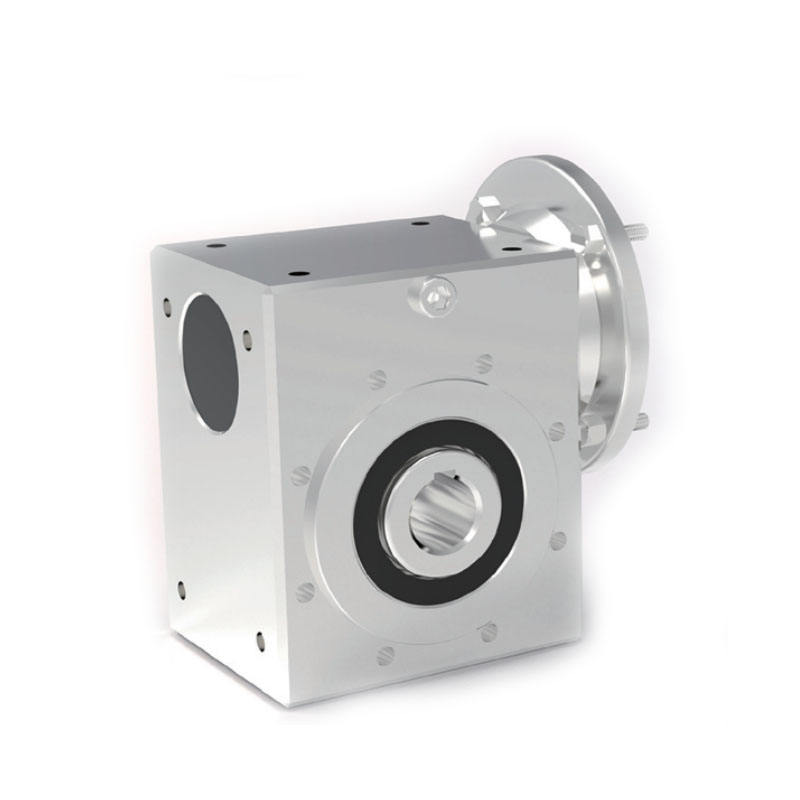

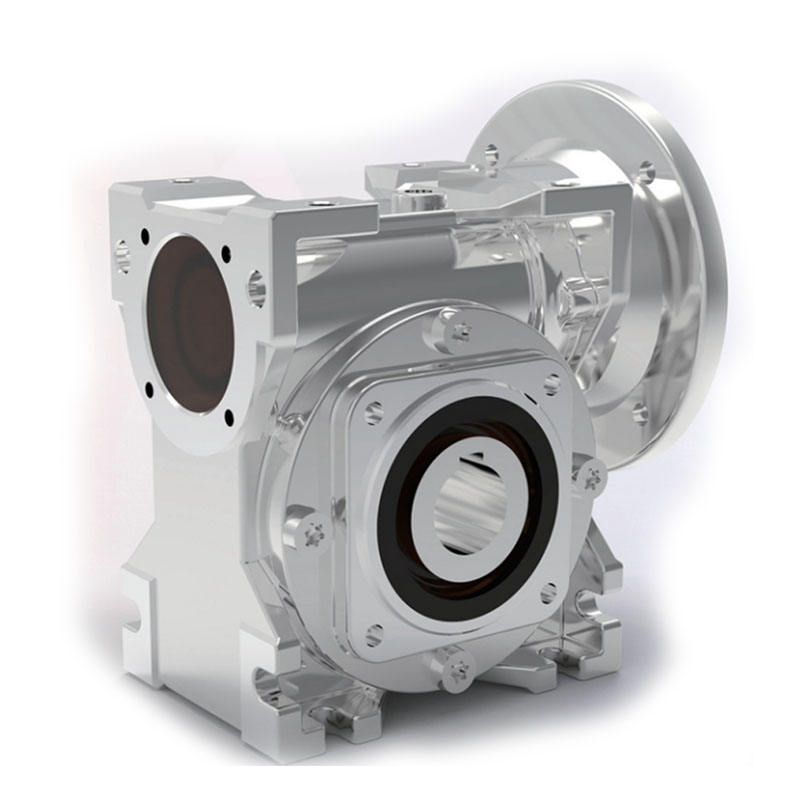

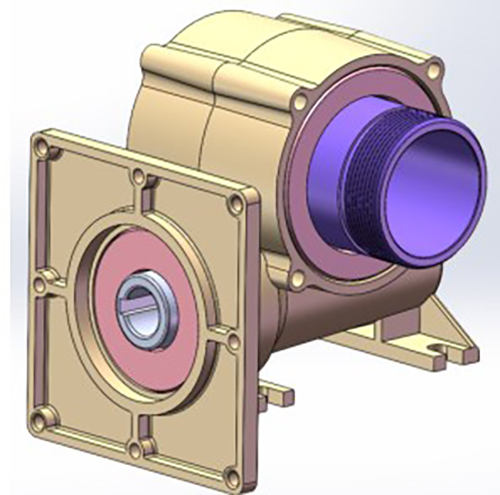

A Worm Gearboxes is a type of gear system that consists of a worm (which resembles a screw) and a worm wheel (which resembles a standard gear). This configuration allows for high torque output and precise speed reduction in a compact design. Worm gearboxes are widely used in various industrial applications due to their efficiency, durability, and ability to provide high reduction ratios in a single stage.

Our worm gearboxes come in various sizes and specifications to meet diverse needs. Below is a table summarizing the key parameters for our standard models.

| Model | Ratio Range | Input Power (kW) | Output Torque (Nm) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|---|

| WG-50 | 5:1 to 30:1 | 0.12 - 0.75 | 30 - 150 | 85 - 90 | 2.5 |

| WG-75 | 10:1 to 60:1 | 0.25 - 1.5 | 100 - 400 | 88 - 92 | 5.0 |

| WG-100 | 15:1 to 100:1 | 0.55 - 3.0 | 250 - 800 | 90 - 94 | 8.5 |

| WG-150 | 20:1 to 100:1 | 1.1 - 7.5 | 500 - 2000 | 92 - 96 | 15.0 |

Additional parameters include input speeds up to 3000 RPM, operating temperatures from -20°C to 100°C, and protection ratings such as IP65 for dust and water resistance. Custom configurations are available upon request to suit specific application requirements.

Worm gearboxes offer several benefits compared to helical, planetary, or bevel gearboxes. They provide higher reduction ratios in a compact form, are often more cost-effective for low to medium power applications, and have inherent self-locking features that add safety. However, they may have slightly lower efficiency at higher ratios, but advancements in materials and design have minimized this drawback.

What is the typical efficiency range of a worm gearbox?

The efficiency typically ranges from 85% to 96%, depending on the ratio, material, and lubrication. Higher ratios may have lower efficiency due to increased friction.

Can worm gearboxes be used in reversible applications?

Yes, but with caution. While they are not inherently reversible due to the self-locking feature, some designs allow for reversible operation if the worm is driven from the output side, though this may reduce efficiency and require specific engineering.

How do I select the right worm gearbox for my application?

Consider factors such as required torque, speed reduction ratio, input power, space constraints, and environmental conditions. Our product table above provides a guideline, and consulting with our technical team can help ensure the best fit.

What maintenance is required for worm gearboxes?

Regular lubrication is essential to minimize wear and maintain efficiency. Check oil levels every 500 hours of operation and replace lubricant annually or as per manufacturer recommendations. Inspect for leaks, noise, or vibration periodically.

Are worm gearboxes suitable for high-speed applications?

They are generally designed for moderate input speeds up to 3000 RPM. For higher speeds, consider alternative gear types or custom solutions to avoid excessive heat and wear.

What materials are used in the worm and worm wheel?

The worm is typically made from hardened steel for durability, while the worm wheel is often composed of bronze or other non-ferrous materials to reduce friction and wear. This combination ensures long life and reliable performance.

Can I mount a worm gearbox in any orientation?

Most models are designed for versatile mounting, including foot-mounted, flange-mounted, or shaft-mounted configurations. Ensure proper lubrication distribution by following the manufacturer's guidelines for orientation.

How does the self-locking feature work?

The self-locking mechanism occurs due to the angle of the worm thread, which creates high friction that prevents the worm wheel from back-driving the worm. This is particularly useful in applications like lifts or hoists where safety is critical.

What is the lifespan of a typical worm gearbox?

With proper maintenance and under normal operating conditions, a worm gearbox can last over 10,000 hours. Factors such as load, speed, and environment can affect longevity, so regular monitoring is advised.

Are there customization options available?

Yes, we offer custom worm gearboxes tailored to specific needs, including special ratios, materials, seals, or mounting options. Contact our sales team with your requirements for a quote.