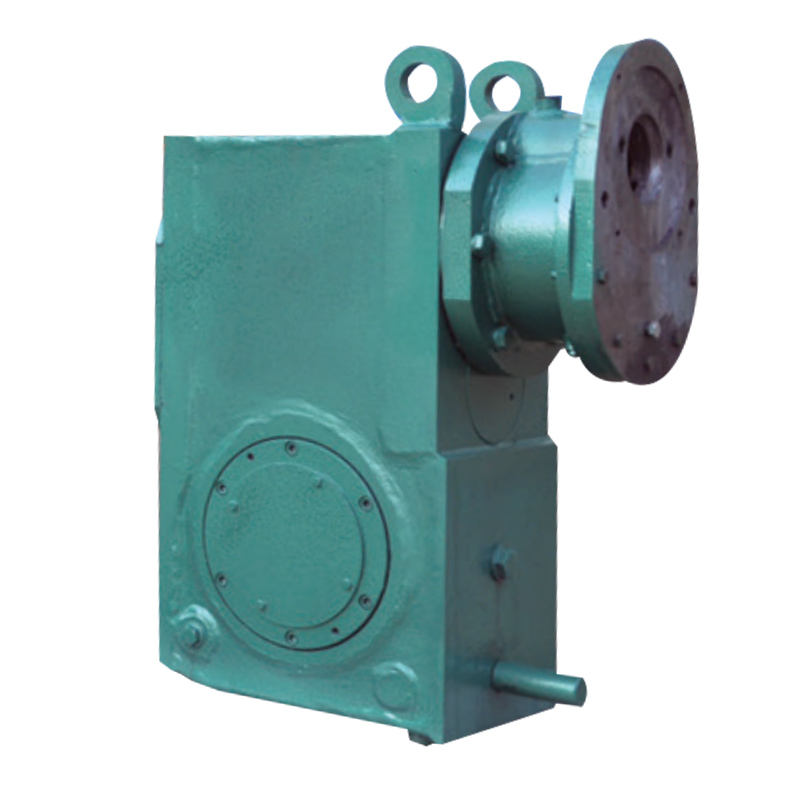

Gearboxes and reducers are mechanical devices used to transmit power and modify torque and speed between a driving device (like an electric motor) and a driven load. They play a critical role in various industrial applications, ensuring efficient operation and longevity of machinery. These components are essential for optimizing performance in systems requiring precise motion control, such as conveyor belts, mixers, and heavy machinery. By reducing speed and increasing torque, gearboxes help match the output of motors to the requirements of the application, improving energy efficiency and reducing wear on equipment.

Our gearboxes and reducers are engineered with precision to meet the highest industry standards. Below are the key parameters that define our product range, ensuring reliability and performance in diverse conditions.

| Parameter | Range/Value | Description |

|---|---|---|

| Gear Ratio | 5:1 to 100:1 | Defines speed reduction; higher ratios provide more torque. |

| Rated Torque (Nm) | 10 - 20,000 Nm | Maximum sustainable torque without damage. |

| Efficiency (%) | 90% - 98% | Energy efficiency under full load conditions. |

| Input Speed (RPM) | Up to 3000 RPM | Maximum speed at the input shaft. |

| Output Speed (RPM) | 1 - 600 RPM | Speed after reduction, based on ratio. |

| Backlash (arc-min) | < 5 arc-min | Precision measure for applications requiring accuracy. |

| Mounting Type | Foot, Flange, Shaft | Installation options for various machinery setups. |

| IP Rating | IP55, IP65, IP67 | Ingress protection against dust and water. |

| Lubrication Type | Synthetic Oil/Grease | Lubrication method and maintenance interval. |

| Weight (kg) | 2 - 500 kg | Varies by size and material, affecting portability. |

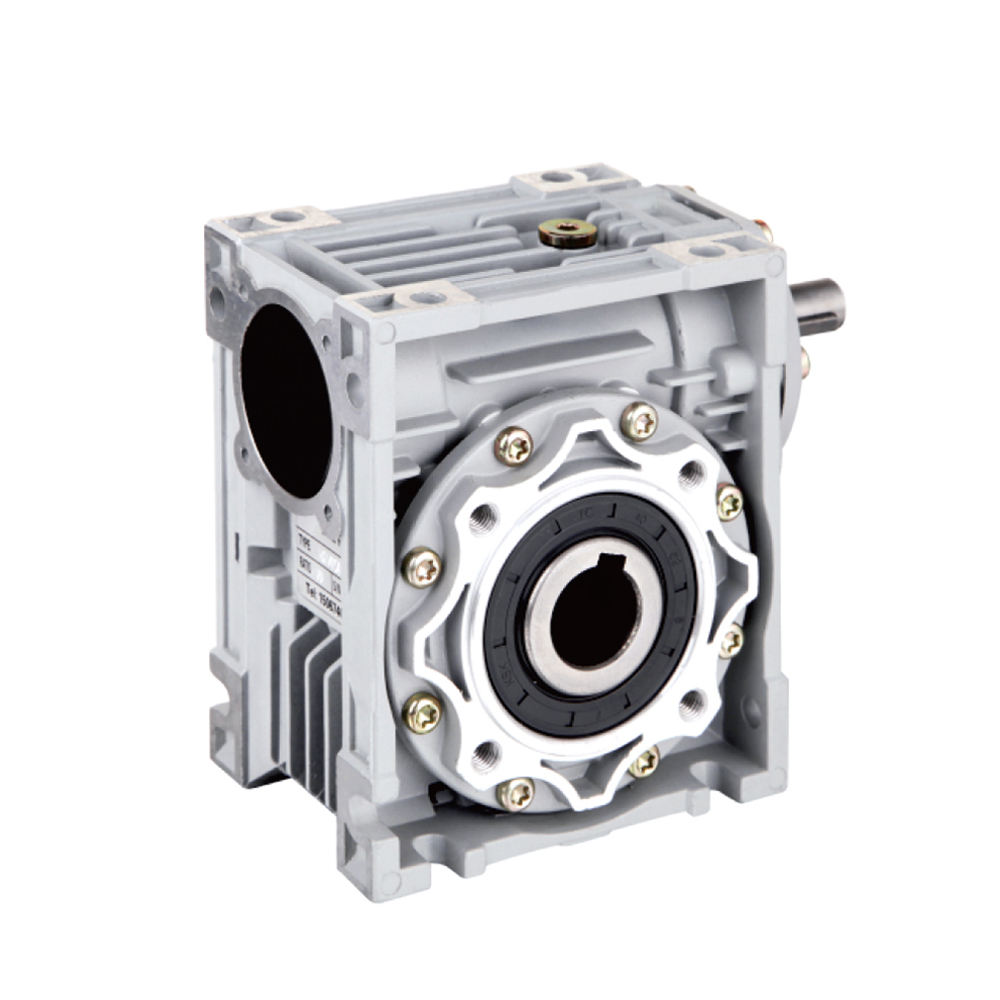

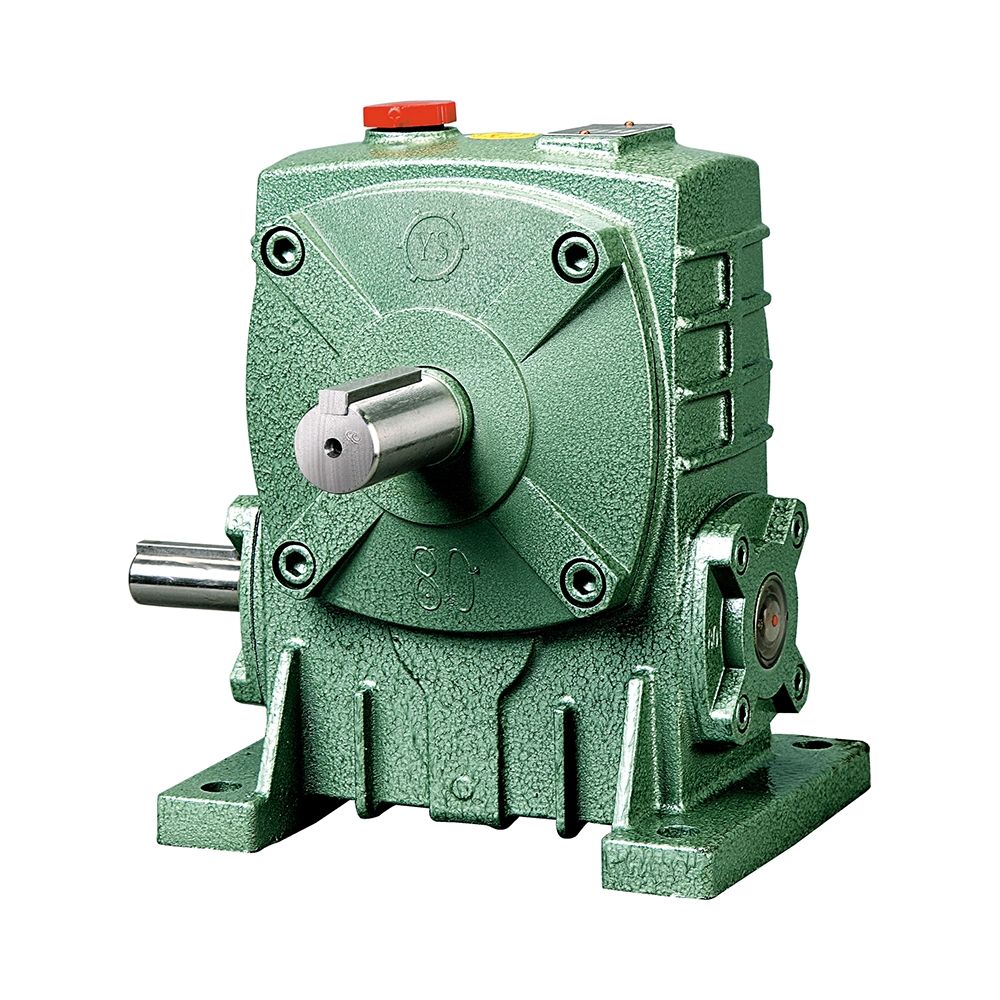

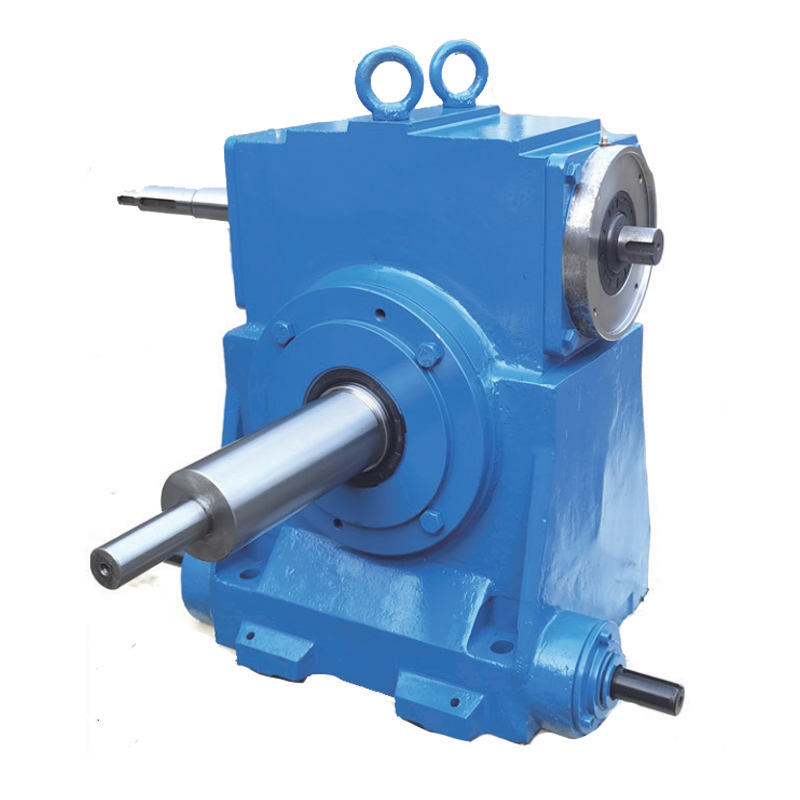

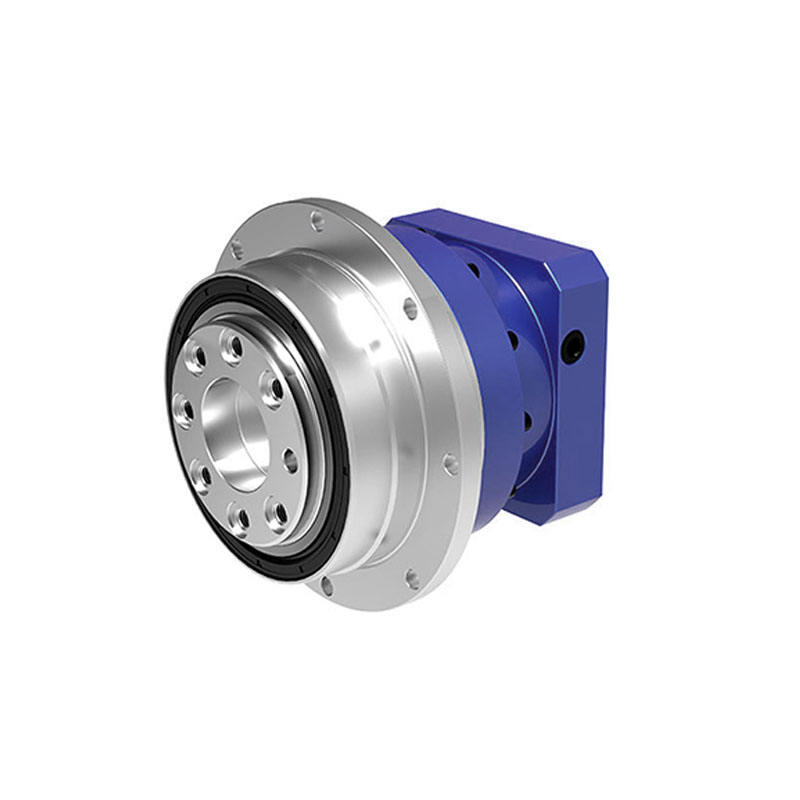

Our product line includes a variety of gearboxes and reducers tailored to specific industrial needs. Each type is designed with unique features to handle different operational demands.

Gearboxes and reducers are integral to numerous industries, enhancing performance and reliability. Common applications include:

What is the difference between a gearbox and a reducer?

A gearbox is a broad term for any system of gears that transmits power, while a reducer specifically refers to a gearbox that reduces speed and increases torque. In practice, the terms are often used interchangeably, but reducers are a subset of gearboxes focused on reduction functions.

How do I select the right gearbox for my application?

Consider factors such as required torque, speed ratio, efficiency, mounting position, and environmental conditions. Calculate the load torque and speed, and match it with the gearbox's rated capacity. Consulting technical specifications and possibly an engineer can ensure optimal selection.

What maintenance is required for gearboxes?

Regular maintenance includes checking lubrication levels every 3-6 months, inspecting for leaks or wear, and replacing oil or grease as per the manufacturer's guidelines (typically every 10,000-20,000 hours). Proper maintenance extends lifespan and prevents failures.

Can gearboxes be used in high-temperature environments?

Yes, but it depends on the construction and lubrication. Our gearboxes are rated for temperatures up to 90°C with standard lubrication, and special options are available for higher temperatures using synthetic lubricants and heat-resistant materials.

What causes backlash in gearboxes, and how can it be minimized?

Backlash is caused by gaps between gear teeth due to manufacturing tolerances or wear. It can be minimized by using precision gears, pre-loading mechanisms, or selecting gearboxes with low backlash ratings (<5 arc-min) for applications requiring high accuracy.

Are your gearboxes customizable?

Yes, we offer customization options including specific ratios, mounting configurations, materials, and seals to meet unique application requirements. Contact our technical team with your specifications for tailored solutions.

How long do gearboxes typically last?

With proper maintenance, our gearboxes can last 20,000 to 50,000 hours or more, depending on the operating conditions. Factors like load, speed, and environment influence lifespan, so regular monitoring is recommended.

What is the efficiency loss in a gearbox?

Efficiency loss occurs due to friction between gears and bearings, typically ranging from 2% to 10% depending on the type. Helical gearboxes have higher efficiency (up to 98%), while worm gearboxes might have lower efficiency (around 90%) due to sliding contact.

Can I repair a damaged gearbox, or should I replace it?

Minor issues like seal leaks or lubrication problems can often be repaired. However, severe damage to gears or shafts may require replacement. We provide repair services and guidance based on inspection to ensure cost-effectiveness.

Do you offer international certifications for your gearboxes?

Yes, our products comply with international standards such as ISO 9001 for quality management and CE marking for European safety, ensuring reliability and global acceptance.