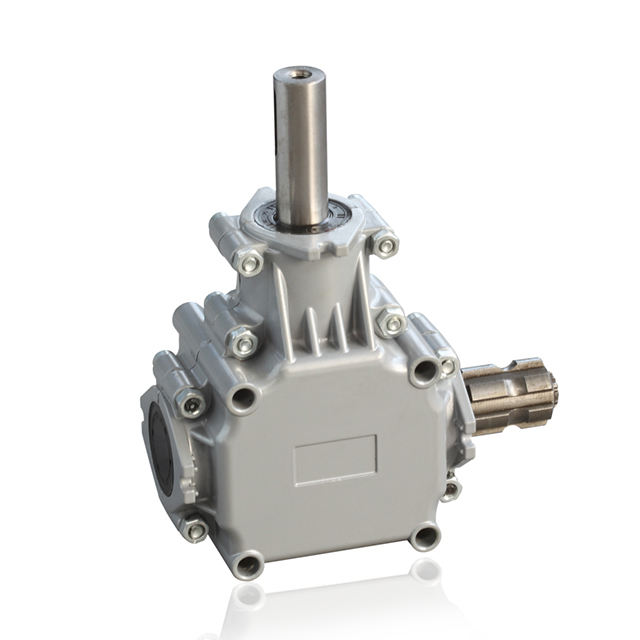

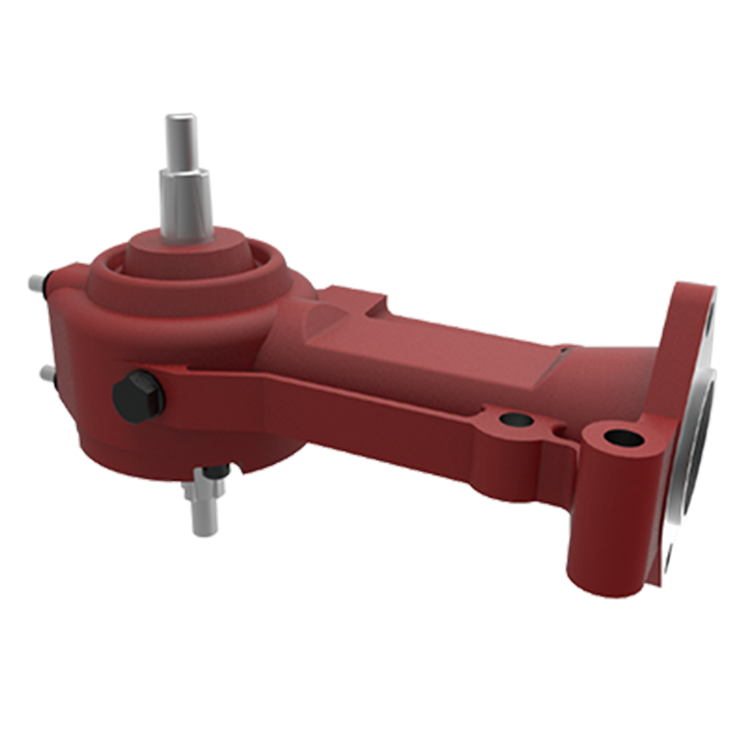

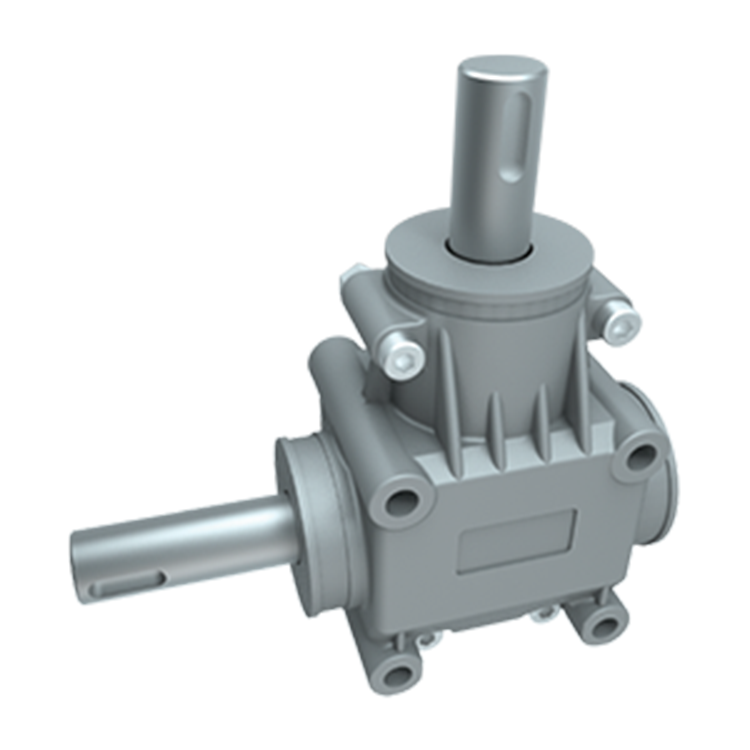

Agricultural gearboxes are critical components in modern farming equipment, designed to transmit power and control speed in various agricultural machinery. These gearboxes ensure efficient operation of tractors, combines, harvesters, and other implements, contributing to productivity and reliability in farming operations. With advancements in technology, agricultural gearboxes have evolved to offer enhanced durability, efficiency, and compatibility with diverse farming needs.

Our agricultural gearboxes are engineered with precision to meet the demanding conditions of farming environments. They feature robust construction, high torque capacity, and resistance to wear and tear. Below are some standout features:

To help you understand the technical aspects, here is a detailed table of our agricultural gearbox models and their specifications:

| Model | Gear Ratio | Input Speed (RPM) | Output Torque (Nm) | Weight (kg) | Material |

|---|---|---|---|---|---|

| AG-100 | 5:1 | 1500 | 500 | 25 | Cast Iron |

| AG-200 | 10:1 | 1200 | 800 | 35 | Steel Alloy |

| AG-300 | 15:1 | 1000 | 1200 | 45 | Hardened Steel |

| AG-400 | 20:1 | 800 | 1500 | 55 | Stainless Steel |

Agricultural gearboxes are versatile and used in various farming equipment. Common applications include:

What is the typical lifespan of an agricultural gearbox?

The lifespan varies based on usage and maintenance, but with proper care, our gearboxes can last 5-10 years or more in standard farming conditions. Regular lubrication and inspection are key to longevity.

How do I choose the right gear ratio for my equipment?

Select a gear ratio based on your machinery's power requirements and operational speed. Consult the equipment manual or our technical support for guidance tailored to your specific needs.

Can agricultural gearboxes be repaired or must they be replaced?

Many gearboxes can be repaired if damage is minor, such as worn gears or seals. However, severe issues may require replacement to ensure safety and efficiency.

What maintenance is required for agricultural gearboxes?

Routine maintenance includes checking oil levels, lubricating moving parts, inspecting for leaks, and cleaning to prevent debris buildup. Follow the manufacturer's schedule for optimal performance.

Are these gearboxes compatible with all tractor brands?

Our gearboxes are designed to be versatile and compatible with major tractor brands, but it's essential to verify specifications such as mounting points and shaft sizes before purchase.

How does weather affect agricultural gearbox performance?

Extreme weather can impact lubrication and material expansion. Use appropriate oils for temperature ranges and consider protective covers in harsh conditions to maintain efficiency.

What materials are used in your gearboxes to ensure durability?

We use high-quality materials like cast iron, steel alloys, and hardened steel, which offer excellent strength and resistance to corrosion and wear.

Is customization available for specific farming needs?

Yes, we offer customization options for gear ratios, sizes, and materials to meet unique agricultural requirements. Contact our team for bespoke solutions.

Proper installation and maintenance are crucial for maximizing the performance of agricultural gearboxes. Ensure alignment during installation, use recommended lubricants, and conduct regular checks to avoid downtime. Always refer to the product manual for specific instructions.