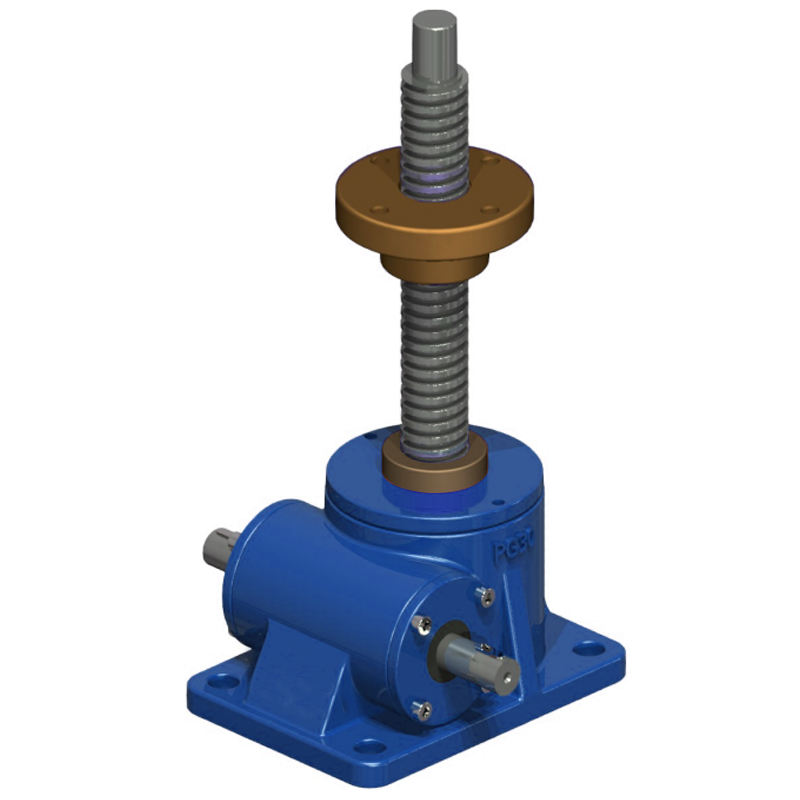

Screw jacks are mechanical devices designed to lift, lower, or position heavy loads with precision and reliability. Widely used in industrial applications, construction, and manufacturing, these systems offer a simple yet effective solution for linear motion. Their durability and ability to handle substantial weights make them a staple in various sectors. This guide delves into the details of screw jack products, covering specifications, types, and common queries to help you make informed decisions.

Below is a list of essential parameters for screw jacks, critical for selection based on your needs:

| Model Series | Max Load Capacity (tons) | Standard Stroke (mm) | Efficiency (%) | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|---|

| SJ-100 | 5 | 200 | 40 | 8 | $150 - $200 |

| SJ-200 | 10 | 300 | 50 | 15 | $250 - $350 |

| SJ-300 | 20 | 500 | 60 | 25 | $400 - $550 |

| SJ-400 | 50 | 800 | 65 | 50 | $700 - $900 |

| SJ-500 | 100 | 1000 | 70 | 100 | $1200 - $1500 |

Screw jacks come in various types to suit different applications. The primary categories include:

Screw jacks are versatile and used in numerous industries. Common applications include:

What is a screw jack and how does it work?

A screw jack is a mechanical device that converts rotational motion into linear motion using a screw mechanism. When you rotate the input shaft, the screw moves vertically to lift or lower a load, providing controlled and stable movement.

What are the maintenance requirements for a screw jack?

Regular maintenance includes lubricating the screw and gears every 3-6 months, inspecting for wear or damage, and ensuring proper alignment. Use high-quality grease or oil based on the operating environment to extend lifespan.

Can screw jacks be used in outdoor environments?

Yes, many screw jacks are made from corrosion-resistant materials like stainless steel and can operate in outdoor conditions. However, it's essential to choose models rated for specific temperatures and environmental factors to prevent degradation.

What is the difference between machine screw jacks and ball screw jacks?

Machine screw jacks have lower efficiency (30-50%) but higher self-locking ability, making them suitable for static loads. Ball screw jacks offer higher efficiency (up to 90%) and are better for dynamic applications requiring frequent movement, but they may need a brake for holding positions.

How do I select the right screw jack for my application?

Consider factors such as load capacity, required travel speed, stroke length, operating environment, and duty cycle. Calculate the total load including any dynamic forces, and consult the manufacturer's specifications to ensure compatibility with your system.

Are screw jacks customizable?

Yes, many manufacturers offer customization options for stroke length, mounting configurations, materials, and accessory integrations like limit switches or motors. Provide detailed requirements to get a tailored solution.

What safety precautions should I take when using screw jacks?

Always ensure the load does not exceed the rated capacity, use multiple jacks for distributed lifting if needed, and secure the base to prevent shifting. Regular inspections and adherence to operational guidelines are crucial to avoid accidents.

How long do screw jacks typically last?

With proper maintenance and within specified load limits, screw jacks can last 10-20 years or more. Lifespan depends on usage frequency, environmental conditions, and the quality of components. High-quality models from reputable brands often offer longer service life.