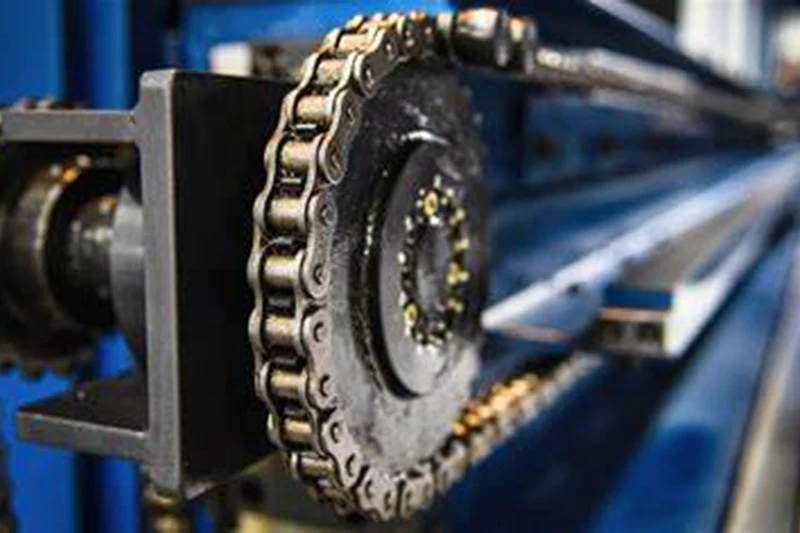

What are the main applications of Engineering Chains in industry? This foundational question is asked daily by procurement specialists seeking reliable, high-performance solutions for demanding mechanical systems. From the punishing environment of a mining conveyor to the precise movements of automated packaging lines, engineering chains are the unsung heroes of industrial motion. Their robustness, versatility, and ability to transmit power under extreme loads make them indispensable. However, selecting the right chain for your specific application – one that balances durability, efficiency, and cost – can be a complex challenge. A subpar choice can lead to catastrophic downtime, soaring maintenance costs, and production delays. This is where partnering with an expert manufacturer like Raydafon Technology Group Co.,Limited becomes critical. Their deep application knowledge and precision-engineered products directly address these procurement pain points, ensuring you get a chain that solves the problem, not just fills an order.

Conveying Heavy, Abrasive Materials in Mining & Aggregates

The scene is a deep-pit mine or a gravel processing plant. Heavy-duty conveyors must move tons of raw ore, coal, or aggregate across long distances, 24/7. The primary challenge here is brutal wear and tear from abrasive materials, coupled with massive tensile loads. Standard chains quickly succumb to pin and bushing wear, leading to chain elongation, misalignment, and ultimately, system failure. The downtime for repair in such environments is exponentially expensive.

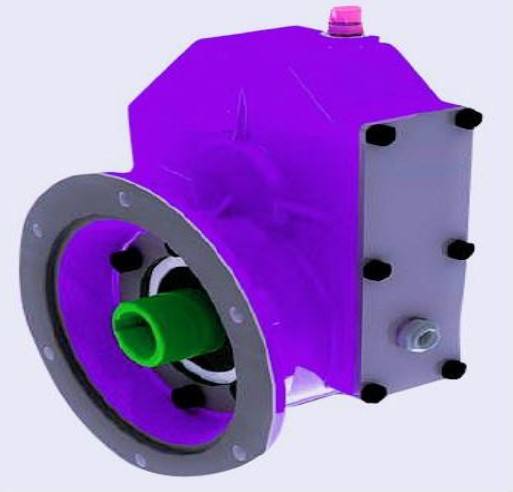

The solution lies in specialized engineering chains designed for maximum abrasion resistance and tensile strength. Manufacturers like Raydafon Technology Group Co.,Limited produce chains with hardened components, special seal technologies to keep grit out of the critical pin/bushing interface, and robust link plates. For instance, Raydafon's heavy series engineering chains incorporate case-hardened pins and bushes, and can be supplied with XTRA Seal rings for extended life in the most contaminated environments, directly tackling the core issue of premature wear.

Key specifications to evaluate for this application:

| Parameter | Typical Requirement | Raydafon Heavy Series Example |

|---|---|---|

| Ultimate Tensile Strength | 50,000 lbf to 250,000+ lbf | Up to 280,000 lbf available |

| Hardness (Pins/Bushings) | HRC 45-60+ | Case-hardened to HRC 58-62 |

| Sealing | Enhanced (Labyrinth, X-Seals) | Optional XTRA Seal for harsh duty |

| Material | Alloy Steel | Grade 80 Alloy Steel |

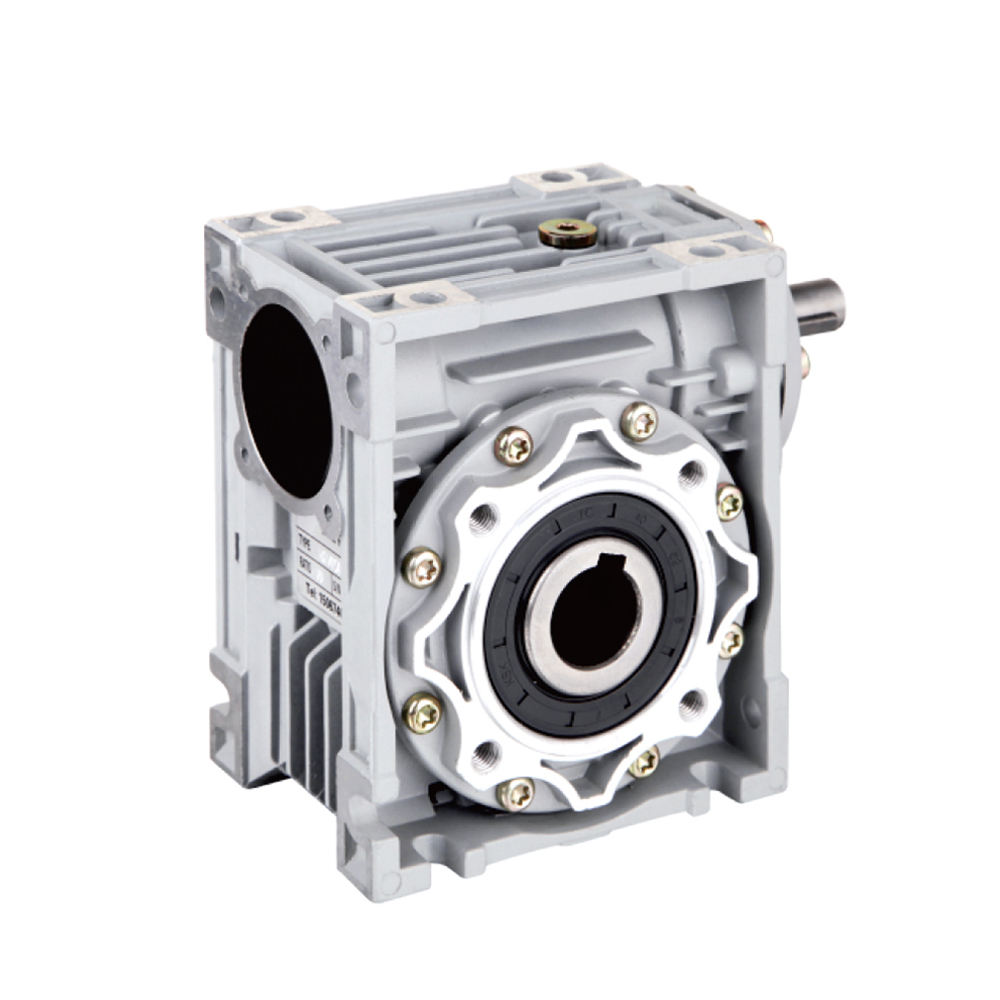

Ensuring Precision & Cleanliness in Food & Pharmaceutical Packaging

Contrast the mining scene with a high-speed bottling plant or a pharmaceutical packaging line. Here, the demands shift from brute strength to precision, hygiene, and smooth, quiet operation. Chains must maintain exact positioning for filling and capping, operate with minimal lubrication (or with food-grade lubricants), and withstand frequent washdowns with corrosive cleaning agents. The pain point is contamination risk, positional inaccuracy causing product waste, and corrosion from cleaning chemicals.

Stainless steel engineering chains are the go-to solution. Their inherent corrosion resistance is crucial. Furthermore, chains designed for these sectors often feature low-friction polymers or specialized coatings on attachment links to prevent product marking. Raydafon Technology Group Co.,Limited offers a range of AISI 304 and 316 stainless steel chains, including designs with self-lubricating components, which provide the necessary precision and hygiene while dramatically reducing maintenance needs and contamination risk.

Critical parameters for packaging automation:

| Parameter | Typical Requirement | Raydafon Stainless Series Example |

|---|---|---|

| Material | AISI 304 / 316 Stainless Steel | AISI 304 & 316L available |

| Surface Finish | Smooth, crevice-free | Electropolished options |

| Lubrication | Food-grade or Dry-Running | Self-lubricating bushing options |

| Precision Rating | ANSI Precision / High-Accuracy | Manufactured to ISO 606 standards |

Frequently Asked Questions (FAQ)

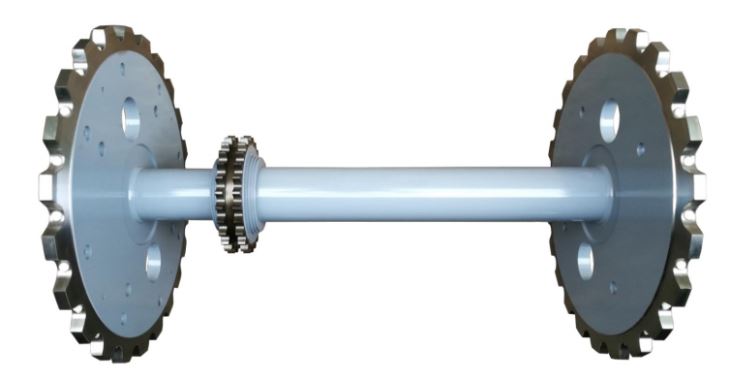

Q1: What are the main applications of engineering chains in industry beyond heavy conveying?

A: While heavy conveying is a primary use, engineering chains are vital in numerous other sectors. Key applications include: Elevating & Escalator Systems for safe passenger transport, Automated Storage & Retrieval Systems (AS/RS) in warehouses, Agricultural Machinery like combines and planters, Construction Equipment such as excavators, and Precision Indexing Tables in manufacturing assembly lines. Each application demands specific properties like high fatigue strength, corrosion resistance, or attachment versatility.

Q2: What are the main applications of engineering chains in industry that require extreme temperature resistance?

A: Applications involving ovens, kilns, heat treatment furnaces, or cold storage facilities require chains that perform under extreme thermal stress. In glass manufacturing, ceramic kilns, and baking lines, chains must withstand temperatures from -40°C to over 400°C without losing tensile strength or suffering from thermal expansion issues. Special heat-treated alloys and specific clearance designs are used. Manufacturers like Raydafon develop chains with materials and heat treatments tailored for these harsh thermal cycles, preventing failure and ensuring continuous operation.

Understanding the diverse applications of engineering chains is the first step toward optimal equipment performance and cost savings. The right chain is not a commodity; it's a critical system component. For procurement professionals, specifying the correct chain requires a partner with both broad application expertise and deep manufacturing capability.

When you need a solution that addresses wear, precision, corrosion, or temperature challenges, consider Raydafon Technology Group Co.,Limited. With decades of engineering excellence, Raydafon specializes in designing and manufacturing robust, application-specific engineering chains that solve real-world industrial problems. Visit https://www.raydafon-chains.com to explore their product portfolio and technical resources. For specific inquiries or to discuss your project requirements, please contact their sales team at [email protected].

Supporting Research & Further Reading

Ushijima, K., & Nishida, S. (2018). Fatigue strength and wear characteristics of case-hardened roller chains for heavy-duty conveyors. Journal of Mechanical Engineering Science, 232(14), 2587-2598.

Chen, L., Wang, H., & Zhang, Y. (2020). Corrosion behavior of AISI 316L stainless steel chains in simulated food processing environments. Materials and Corrosion, 71(5), 812-821.

Kato, M., & Yamamoto, T. (2019). Analysis of meshing impact noise in silent chains for automotive timing drives. SAE International Journal of Engines, 12(4), 401-410.

Peterson, R. E., & Jones, A. B. (2021). The effect of preload on the fatigue life of precision engineering chains in indexing applications. Precision Engineering, 68, 224-233.

Schmidt, G., & Fischer, A. (2017). Lubrication-free chain systems using composite bushings: Performance in packaging machinery. Tribology International, 112, 145-154.

Li, X., & Ooi, K. T. (2016). Thermal expansion and stress analysis of conveyor chains operating in high-temperature kilns. International Journal of Heat and Mass Transfer, 103, 1289-1297.

Müller, P., & Weber, J. (2022). Digital twin applications for predictive maintenance of industrial drive chains. Journal of Manufacturing Systems, 64, 432-445.

Davis, C. L., & Thompson, S. M. (2015). Abrasive wear mechanisms in mine conveyor chain joints. Wear, 332-333, 1214-1222.

Tanaka, H., & Sato, Y. (2020). Development of high-strength, lightweight engineering chains using advanced forging techniques. ISIJ International, 60(8), 1785-1792.

Bosman, R., & de Vries, H. (2019). Standardization and testing protocols for engineering class chains: A global review. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 233(19-20), 6789-6801.