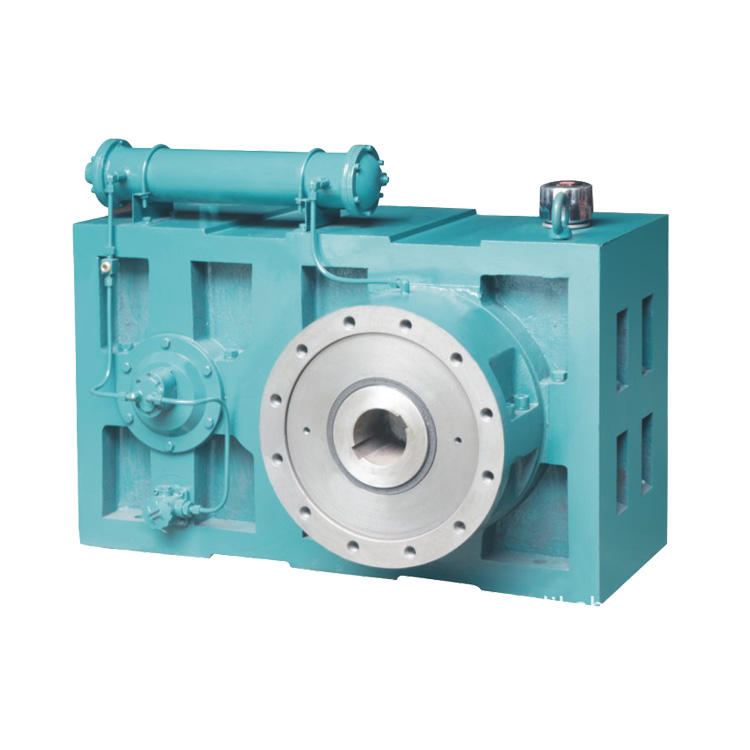

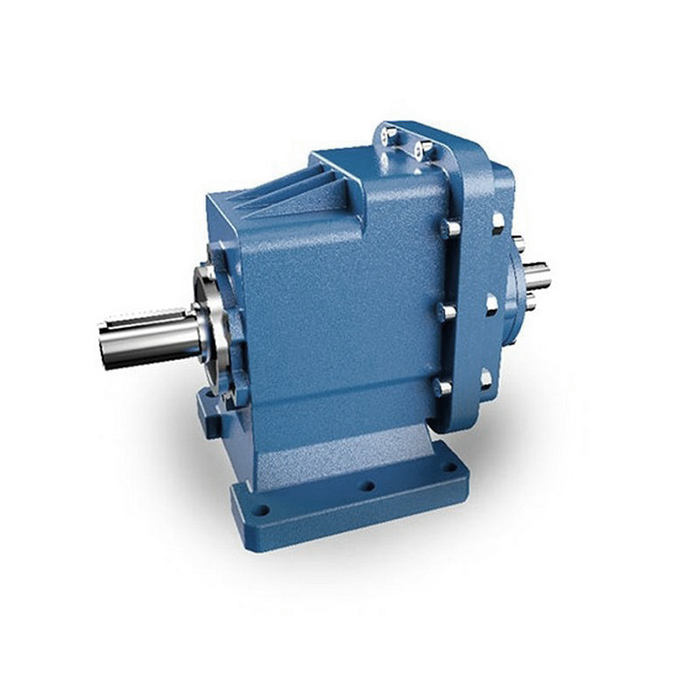

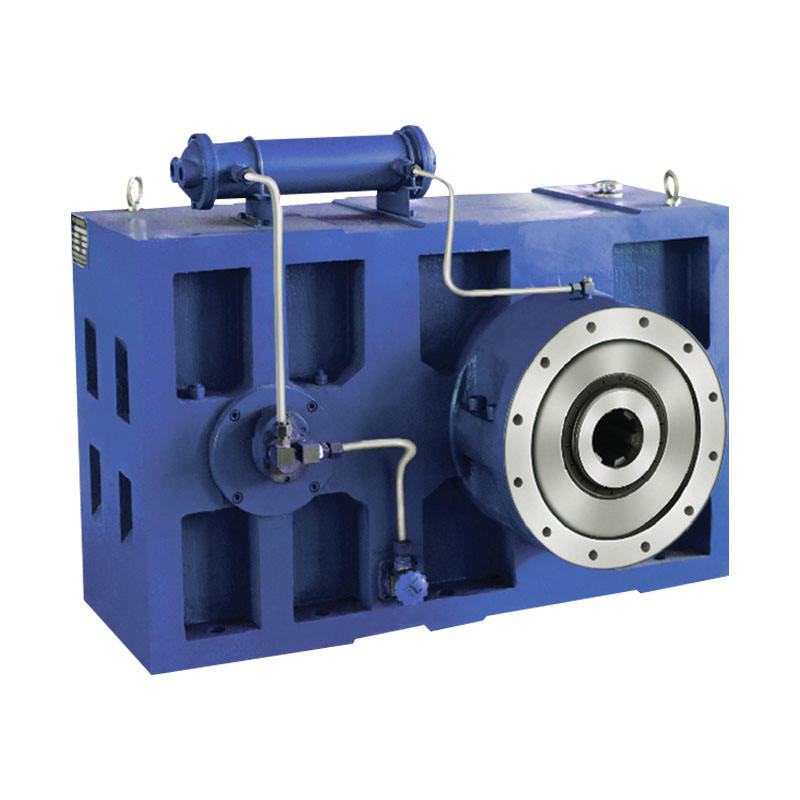

Helical gearboxes are a type of mechanical transmission system widely used in various industrial applications due to their efficiency, durability, and smooth operation. These gearboxes utilize helical gears, which have teeth cut at an angle to the gear axis, allowing for gradual engagement and reduced noise and vibration compared to spur gears. This design makes them ideal for high-speed and high-torque applications, such as in manufacturing, automotive, and heavy machinery sectors.

Our helical gearboxes are engineered to meet rigorous industrial standards. Below is a detailed table of specifications for our standard models.

| Model | Ratio Range | Input Power (kW) | Output Torque (Nm) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|---|

| HG-100 | 5:1 to 20:1 | 0.12 - 22 | Up to 500 | 96 | 15 |

| HG-200 | 10:1 to 40:1 | 0.25 - 45 | Up to 1000 | 97 | 30 |

| HG-300 | 15:1 to 60:1 | 0.37 - 90 | Up to 2000 | 98 | 50 |

| HG-400 | 20:1 to 80:1 | 0.55 - 160 | Up to 4000 | 98 | 80 |

Additional parameters include input speeds up to 3000 RPM, operating temperatures from -20°C to 120°C, and protection ratings up to IP65 for dust and water resistance. All models are customizable with various mounting options, such as foot-mounted, flange-mounted, or shaft-mounted configurations.

Helical gearboxes are utilized in numerous industries due to their reliability and performance. Common applications include:

Compared to spur or bevel gearboxes, helical gearboxes offer several benefits:

What is the main advantage of a helical gearbox?

The primary advantage is its smooth and quiet operation, thanks to the helical gear design that allows for gradual tooth engagement, reducing noise and vibration while increasing efficiency and load capacity.

How do I choose the right helical gearbox for my application?

Consider factors such as required torque, speed ratio, input power, operating environment (e.g., temperature, exposure to elements), and mounting style. Consulting with an engineer or referring to our product specifications table can help select the appropriate model.

Are helical gearboxes maintenance-intensive?

No, helical gearboxes are designed for low maintenance. Regular lubrication and occasional inspections for wear are typically sufficient, thanks to their durable construction and efficient operation.

Can helical gearboxes be used in high-temperature environments?

Yes, our models are rated for operating temperatures from -20°C to 120°C, with options for special seals and lubricants to handle extreme conditions, making them suitable for industries like metal processing or automotive manufacturing.

What materials are used in your helical gearboxes?

We use high-quality materials such as case-hardened steel for gears, cast iron or aluminum for housings, and premium bearings to ensure durability, corrosion resistance, and long-term performance.

How does the efficiency of a helical gearbox compare to others?

Helical gearboxes are among the most efficient, with ratings often between 94-98%, outperforming spur gearboxes (which average 90-95%) due to reduced sliding friction and better load distribution.

Are custom configurations available?

Yes, we offer customization options including specific ratios, mounting types, shaft sizes, and protective coatings to meet unique application requirements. Contact our team for tailored solutions.

What is the typical lifespan of a helical gearbox?

With proper maintenance, our helical gearboxes can last over 20,000 hours of operation, depending on usage conditions. Factors like load, speed, and environment influence longevity.

Do helical gearboxes require special lubrication?

Standard industrial lubricants are suitable, but we recommend using high-quality oils or greases specified in the manual to optimize performance and lifespan. Regular lubrication intervals should be followed based on operating hours.

Can I install a helical gearbox myself?

While installation is straightforward for experienced technicians, we advise professional installation to ensure proper alignment, mounting, and lubrication, which are critical for performance and safety. Our products come with detailed installation guides.