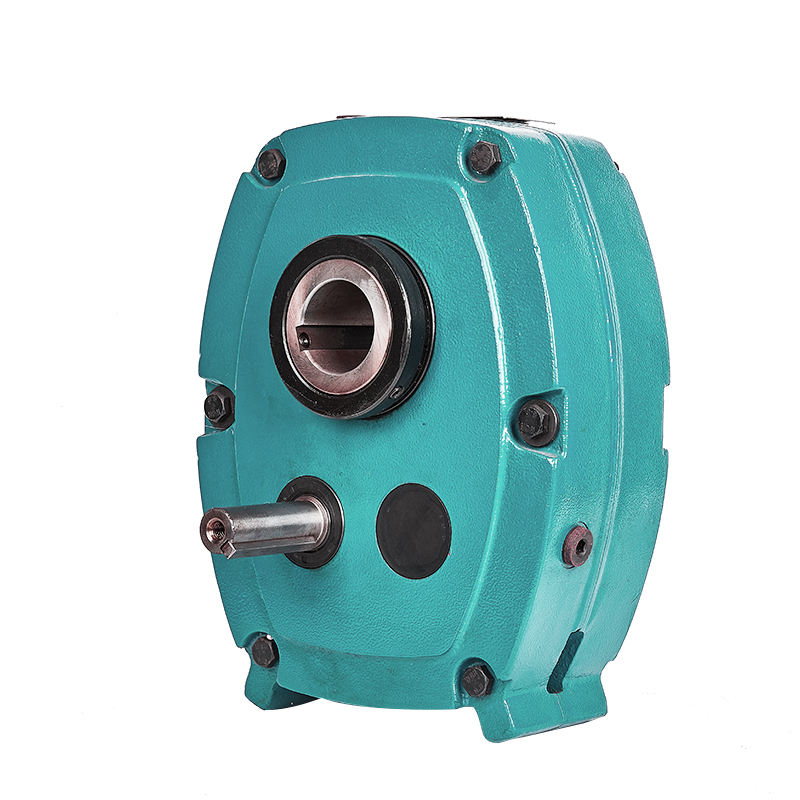

When it comes to industrial machinery and power transmission systems, Shaft Mounted Gearboxes play a crucial role in ensuring efficient and reliable operation. These gearboxes are designed for direct mounting onto the driven shaft, making them a compact and versatile solution for various applications. In this article, we will delve into the details of Shaft Mounted Gearboxes, including their key features, specifications, and common questions, to help you understand why they are an essential component in many industries.

Shaft Mounted Gearboxes are known for their durability and ease of installation. They are typically used in conveyors, mixers, and other equipment where space is limited. The gearbox is mounted directly on the shaft, eliminating the need for additional couplings or foundations, which reduces maintenance and costs. Below, we outline the main product parameters and specifications to give you a comprehensive overview.

| Parameter | Description | Range/Value |

|---|---|---|

| Gear Ratio | The ratio of input to output speed | 5:1 to 100:1 |

| Output Torque | Maximum torque capacity at output shaft | Up to 20,000 Nm |

| Input Power | Power rating for motor input | 0.12 kW to 160 kW |

| Efficiency | Overall mechanical efficiency | 94% to 98% |

| Mounting Position | Possible orientations for installation | Horizontal, vertical, or inclined |

| Weight | Approximate weight of the gearbox | 5 kg to 500 kg |

| Lubrication | Type of lubrication required | Oil bath or grease |

What is a Shaft Mounted Gearbox?

A Shaft Mounted Gearbox is a type of gear reducer that mounts directly onto the driven shaft of machinery, providing torque multiplication and speed reduction without the need for additional components like couplings or baseplates.

How do I install a Shaft Mounted Gearbox?

Installation is straightforward: slide the gearbox onto the shaft, align it properly, and secure it using the provided locking device. Ensure the shaft is clean and free of damage for optimal performance.

What maintenance is required for these gearboxes?

Regular maintenance includes checking lubrication levels every 6 months, inspecting for leaks or wear, and ensuring all bolts are tight. Use the recommended lubricant as per the manufacturer's guidelines.

Can Shaft Mounted Gearboxes be used in harsh environments?

Yes, many models are built with sealed housings and high protection ratings (e.g., IP65) to withstand dusty, wet, or corrosive conditions, making them suitable for industries like mining and agriculture.

What are the common applications?

They are widely used in conveyors, elevators, mixers, crushers, and other equipment where compact power transmission is needed, particularly in material handling, food processing, and manufacturing sectors.

How do I select the right gear ratio?

Choose the gear ratio based on your required output speed and torque. Calculate the ratio by dividing the input speed by the desired output speed, and consider the load characteristics for optimal selection.

Are there custom options available?

Yes, manufacturers often offer customizations such as special coatings, different mounting configurations, or tailored gear ratios to meet specific application requirements.

What is the typical lifespan of a Shaft Mounted Gearbox?

With proper maintenance, these gearboxes can last over 20,000 hours of operation. Lifespan depends on factors like load, environment, and adherence to maintenance schedules.

How does temperature affect performance?

Extreme temperatures can impact lubrication and material expansion. Ensure the gearbox operates within the specified temperature range and use appropriate lubricants for high or low-temperature conditions.

Can I repair a Shaft Mounted Gearbox myself?

Simple maintenance like lubrication can be done in-house, but for major repairs, it's recommended to consult the manufacturer or a certified technician to avoid voiding warranties or causing damage.