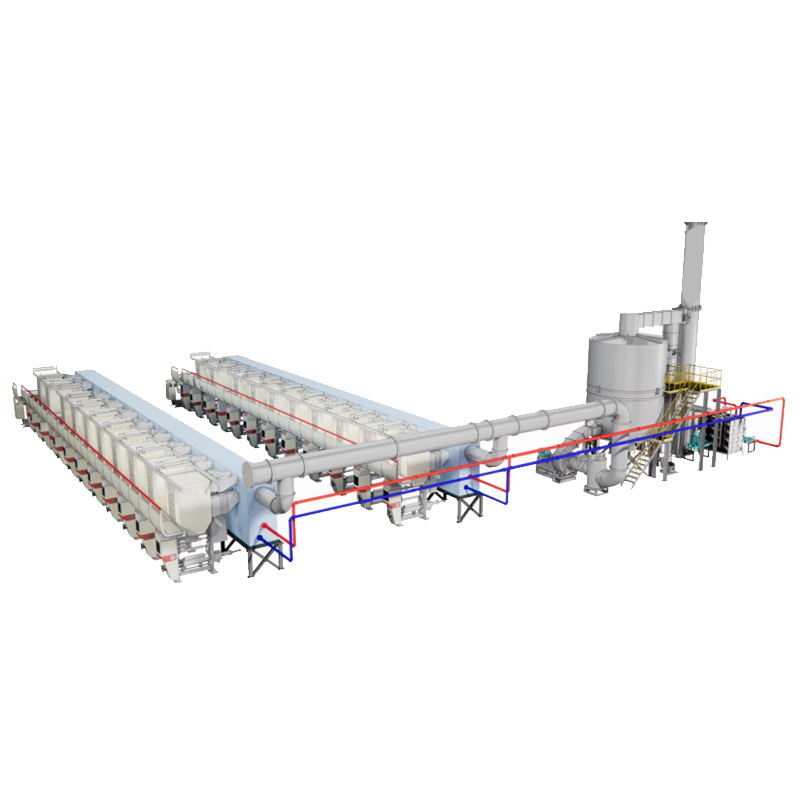

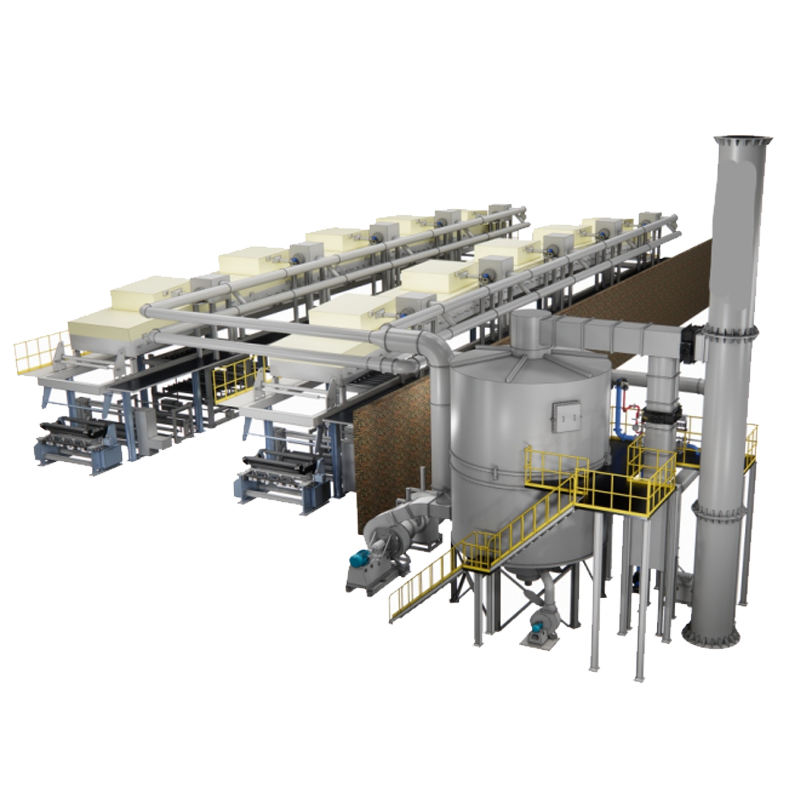

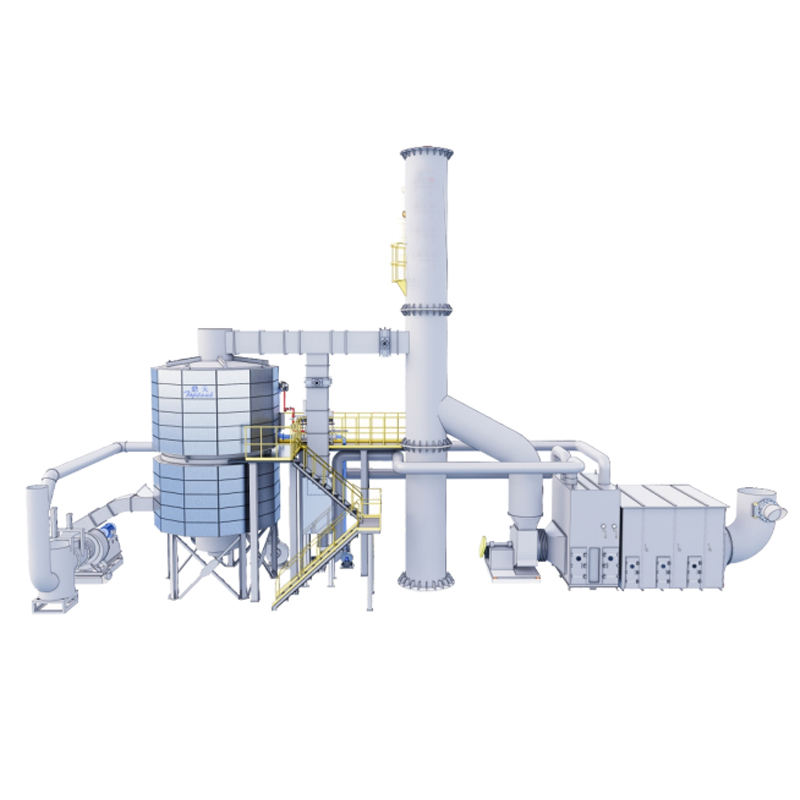

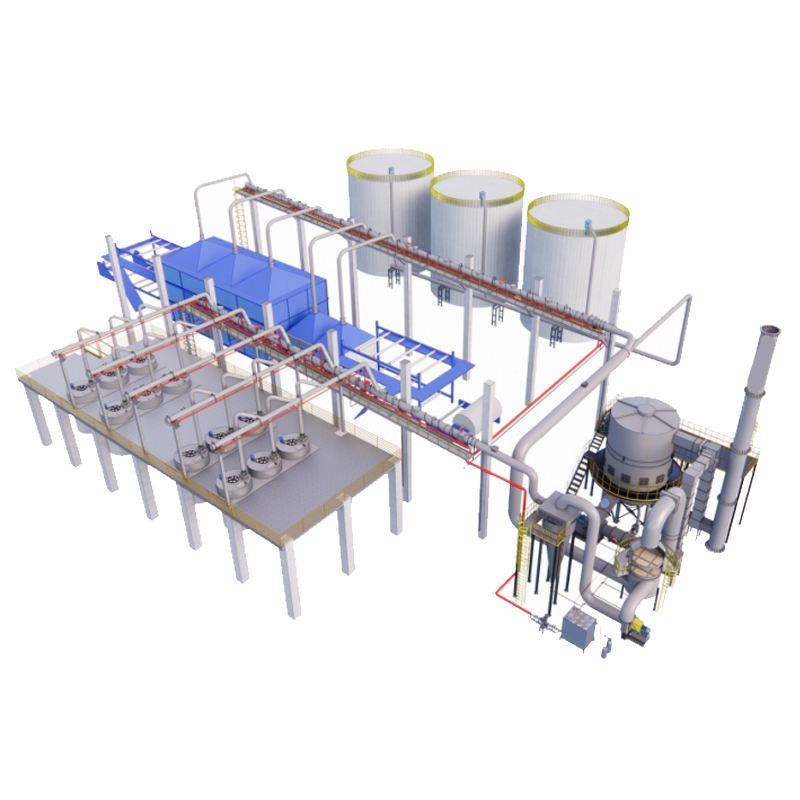

An RTO (Regenerative Thermal Oxidizer) System is an advanced air pollution control technology designed to destroy hazardous air pollutants (HAPs), volatile organic compounds (VOCs), and odorous emissions from industrial processes. It operates at high thermal efficiency by utilizing a ceramic heat exchange media to recover and reuse heat energy, making it a cost-effective and environmentally compliant solution for various industries.

Our RTO System is engineered with precision to meet stringent environmental standards while ensuring operational efficiency. Below are the detailed specifications:

| Parameter | Value | Unit |

|---|---|---|

| VOC Destruction Rate | ≥99% | Percentage |

| Heat Recovery Efficiency | 90-95% | Percentage |

| Maximum Flow Rate | 100,000 | SCFM |

| Operating Pressure | Atmospheric | PSI |

| Electrical Consumption | Varies by size (e.g., 10-200 kW) | Kilowatts |

| NOx Emissions | < 5 ppm | Parts per million |

RTO Systems are widely used across industries to control emissions and improve air quality. Common applications include:

Q: How does an RTO System work?

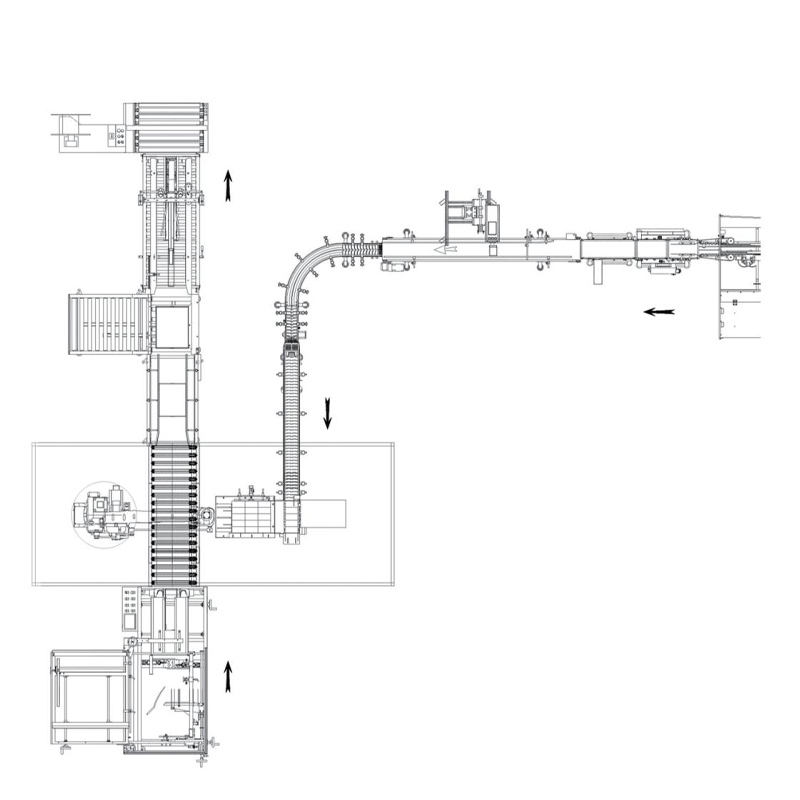

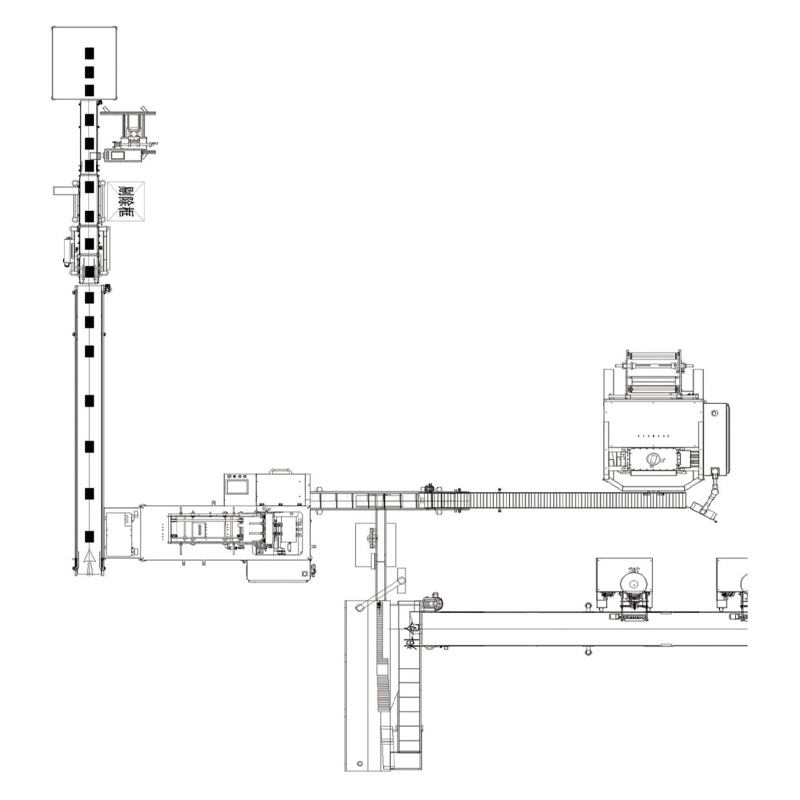

A: An RTO System works by directing contaminated air through ceramic heat exchange media, where it is preheated before entering a combustion chamber. The VOCs are oxidized at high temperatures, and the clean, hot air passes through another ceramic bed, transferring heat back to the media for energy recovery. This cyclic process ensures high efficiency and minimal fuel consumption.

Q: What maintenance is required for an RTO System?

A: Regular maintenance includes inspecting and replacing ceramic media every 3-5 years, checking burners and valves for wear, cleaning pressure sensors, and verifying control system calibration. Annual shutdowns for thorough inspection are recommended to ensure longevity and performance.

Q: Can an RTO System handle high moisture content in the exhaust stream?

A: Yes, RTO Systems are designed to tolerate moisture, but excessive moisture may require pre-treatment such as condensation removal or using specialized media. Our systems include options for handling up to 50% relative humidity without significant efficiency loss.

Q: What is the typical lifespan of an RTO System?

A: With proper maintenance, an RTO System can last 20+ years. Key components like the ceramic media may need replacement every 3-5 years, while the stainless steel structure remains durable under industrial conditions.

Q: How does an RTO compare to other oxidizers like catalytic oxidizers?

A: RTO Systems offer higher thermal efficiency (up to 95% heat recovery) compared to catalytic oxidizers (typically 70-85%), making them more fuel-efficient for high flow rates. However, catalytic oxidizers may be preferable for lower temperature applications. The choice depends on specific emission profiles and operational costs.

Q: Are RTO Systems customizable for specific industry needs?

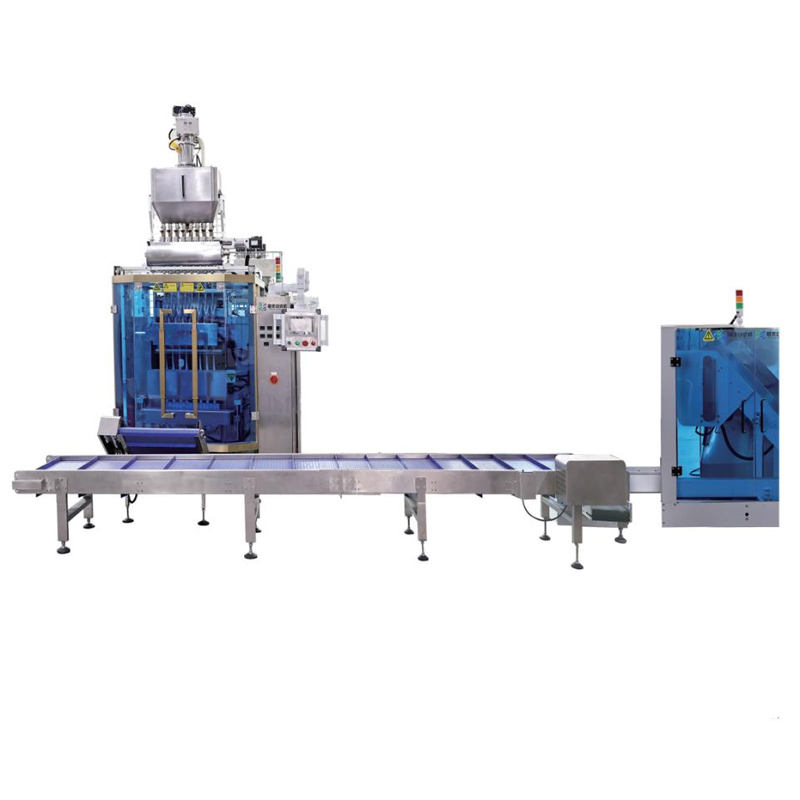

A: Absolutely. Our RTO Systems are tailored to client requirements, including size, flow capacity, material compatibility, and automation features. We provide design consultations to ensure optimal integration with existing processes.

Our team provides end-to-end support, from site assessment and system design to installation, commissioning, and ongoing maintenance. We offer training for operators and 24/7 technical assistance to ensure seamless operation.