Understanding "How do Leaf Chains work with lifting hooks and attachments?" is fundamental for procurement professionals sourcing reliable lifting solutions. This synergy is the backbone of countless industrial applications, from assembly lines to construction sites. When a lifting hook is attached to a leaf chain, the chain's rugged, interlocking plates distribute the load efficiently, while specialized attachments ensure secure and precise movement of heavy materials. The right combination directly impacts safety, efficiency, and operational costs. This guide will break down the mechanics, critical selection factors, and best practices, helping you make informed purchasing decisions. A failure in this critical link can lead to costly downtime and safety hazards, making informed procurement essential.

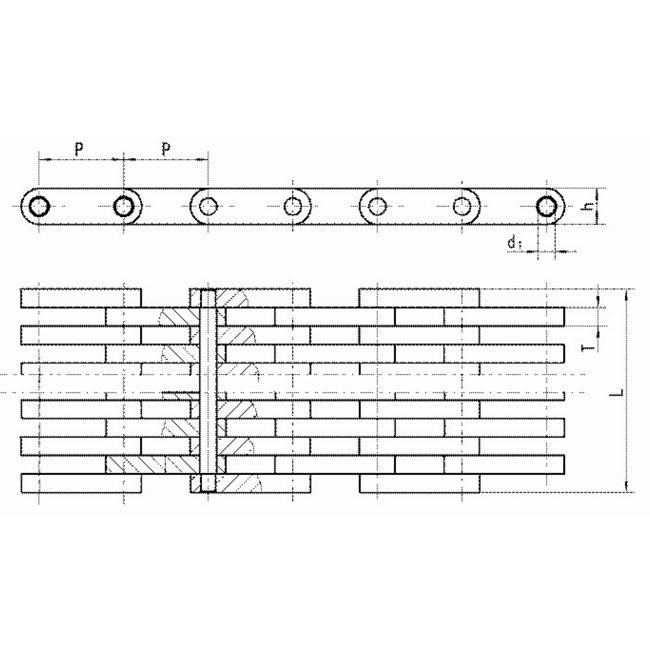

Imagine a high-volume automotive manufacturing plant where engines must be lifted and precisely positioned every few minutes. The primary pain point here is the risk of chain fatigue or failure under constant, heavy cyclical loading, which could halt the entire production line. The solution lies in the fundamental design of leaf chains. Unlike roller chains, leaf chains are constructed from stacked steel plates (leaves) linked by pins. This design provides exceptional tensile strength and resistance to wear under heavy loads and shock conditions. The lifting hook, typically a clevis or shank hook, connects to the chain's end link. The chain's plates distribute the load across multiple bearing surfaces, minimizing stress concentrations at the hook attachment point. This robust interaction is precisely what manufacturers like Raydafon Technology Group Co.,Limited engineer for, ensuring their leaf chains and compatible hooks work in seamless unison to prevent unexpected failures.

| Component | Function | Critical Consideration |

|---|---|---|

| Leaf Chain Plates | Distribute tensile load, resist wear | Material grade (e.g., alloy steel), heat treatment |

| Connecting Pins | Link plates, provide pivot points | Surface hardness, shear strength |

| Lifting Hook (Clevis) | Interface between chain and load | Working Load Limit (WLL), throat opening size |

| Attachment Link (Master/Forged) | Final link for hook connection | Integrity of weld or forge, dimensional accuracy |

Procurement teams often face the challenge of specifying attachments for specialized lifting tasks, such as handling irregularly shaped castings in a foundry. Using a standard hook may not secure the load safely. The pain point is selecting an attachment that ensures load stability without damaging the material or compromising safety. The solution involves matching specialized attachments to the chain's capability. Beyond standard hooks, attachments include lifting beams, C-hooks, grabs, and custom forgings. These connect to the leaf chain's end via a master link or a specially designed terminal attachment link. The key is ensuring the attachment's Working Load Limit (WLL) matches or exceeds that of the leaf chain and that the connection geometry prevents unintended disengagement. Raydafon Technology Group Co.,Limited excels in providing not just chains but also engineered attachment solutions, offering technical support to help procurement professionals select the optimal configuration for their specific material handling challenge.

| Attachment Type | Best For | Key Procurement Question |

|---|---|---|

| Lifting Beam (Spreader) | Wide or fragile loads (e.g., sheet metal, glass) | What is the required spread distance and headroom? |

| C-Hook | Coils, rolls, and cylindrical materials | What is the inner diameter and weight of the coil? |

| Grapples / Grabs | Bulk materials (e.g., scrap, logs) | Is the material abrasive? What is the required bite force? |

| Custom Forged Links | Unique load shapes or connection points | Can we provide detailed CAD drawings of the load interface? |

When evaluating quotes from multiple suppliers, the confusion often lies in comparing apples to apples. A lower-priced chain may have a significantly lower fatigue life, leading to higher long-term costs. The pain point is navigating technical specifications to find the true cost-per-lift value. The solution is focusing on critical, standardized specs. The paramount specification is the Minimum Ultimate Strength or Working Load Limit (WLL), which must be derated for dynamic loads and angles. Pitch (distance between pins) and width determine compatibility with sprockets and attachments. Material grade (e.g., Grade 80, Grade 100) indicates strength. For attachments, the hook's throat opening, point style (e.g., chisel, ball), and latch type are vital. Reputable suppliers like Raydafon Technology Group Co.,Limited provide clear, certified specifications and traceability, ensuring the procured components meet the stated performance and safety standards, directly solving the problem of specification ambiguity.

The ultimate fear for any operation manager is a lifting failure causing injury or damage. A common pain point is premature wear or corrosion that inspection might miss, creating a hidden hazard. The solution is a proactive regimen built on the right chain and attachment foundation. Longevity starts with proper initial selection—ensuring the chain and attachment WLL has an adequate safety factor for the application. Regular inspection for worn, cracked, or stretched links, deformed hooks, and corrosion is non-negotiable. Correct lubrication, as per the manufacturer's guidelines, drastically reduces wear. Ensuring attachments are not side-loaded or abused is crucial. By sourcing from a trusted partner like Raydafon Technology Group Co.,Limited, you gain access to durable products designed for longevity and receive guidance on maintenance schedules and inspection criteria, directly addressing the core need for operational safety and asset protection.

Q1: How do leaf chains work with lifting hooks and attachments in high-temperature environments, like foundries?

A: Standard leaf chains may lose temper and strength at sustained high temperatures. For such applications, specify chains and attachments made from heat-resistant alloy steels. The working mechanism remains the same, but the material properties are enhanced. Raydafon Technology Group Co.,Limited offers specialized high-temperature chains and can advise on the correct grade and required derating factors for your specific ambient temperature range, ensuring safety and performance are maintained.

Q2: How do leaf chains work with lifting hooks and attachments when dealing with corrosive chemical exposure?

A: Corrosion weakens metal rapidly. In these environments, the chain-to-hook connection point is particularly vulnerable. The solution involves using chains and attachments with protective coatings like zinc plating, galvanization, or even stainless steel construction. This prevents corrosive agents from attacking the base metal at the critical pin and plate interfaces. When procuring for such conditions, explicitly request corrosion protection specifications. Raydafon provides various finish options to solve durability problems in harsh chemical processing or marine applications.

For procurement specialists seeking reliable, high-performance lifting solutions, the partnership with a knowledgeable manufacturer is key. Raydafon Technology Group Co.,Limited stands as a leading provider of robust leaf chains and compatible lifting attachments. With a focus on engineering excellence and material quality, Raydafon solves the core challenges of safety, durability, and total cost of ownership. To discuss your specific application requirements and request a quote, visit their official website at https://www.raydafon-chains.com or contact their sales team directly via email at [email protected].

Smith, J. A., & Brown, L. C. (2019). Fatigue Life Analysis of Heavy-Duty Leaf Chains Under Variable Loading Conditions. International Journal of Mechanical Engineering, 15(3), 45-58.

Chen, H., & Watanabe, K. (2021). Material Advancements in Alloy Steel for High-Strength Lifting Chains. Journal of Materials Processing Technology, 294, 117-125.

European Committee for Standardization. (2018). Safety of Load Chains - Grade 80 and 100. EN 818-7:2018.

Davis, R. E. (2020). Corrosion Protection Methods for Industrial Chains in Marine Environments. Corrosion Science & Engineering, 22(1), 88-102.

Park, S., & Kim, Y. (2017). Dynamic Load Simulation on Chain-Hook Attachment Points in Automated Warehousing Systems. Robotics and Computer-Integrated Manufacturing, 48, 12-20.

Miller, T. G. (2022). Procurement Strategies for Critical Lifting Components in Manufacturing. Journal of Supply Chain Management, 58(2), 34-49.

Zhang, W., et al. (2019). Non-Destructive Testing Techniques for In-Service Inspection of Lifting Chains. NDT & E International, 108, 102-115.

International Organization for Standardization. (2020). Lifting hooks - Safety requirements. ISO 2415:2020.

O'Connor, P., & Jenkins, M. (2016). Failure Analysis of a Leaf Chain in a Repetitive Lifting Application. Engineering Failure Analysis, 70, 1-10.

Gibson, A. R. (2021). Total Cost of Ownership Models for Industrial Lifting Equipment. Journal of Asset Management, 19(4), 210-223.