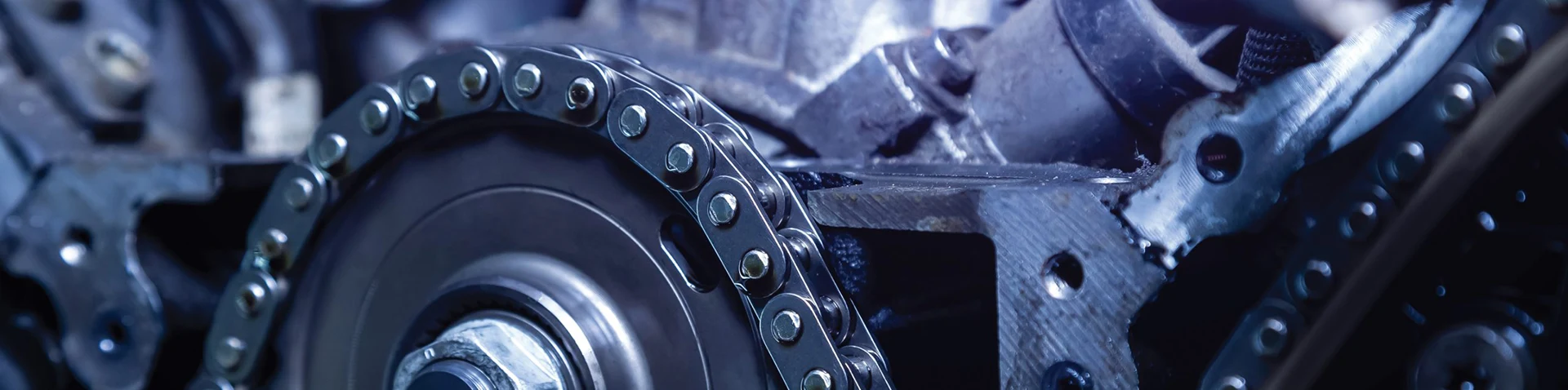

What Are Engineering Chains and Why Are They Essential in Modern Industry?

Engineering chains are critical components in various industrial applications, designed to transmit power, convey materials, or handle heavy loads with precision and durability. These chains are engineered to meet specific operational demands, ensuring reliability in harsh environments. In this comprehensive guide, we delve into the product parameters, features, and common questions surrounding engineering chains, providing you with the technical insights needed for informed decision-making.

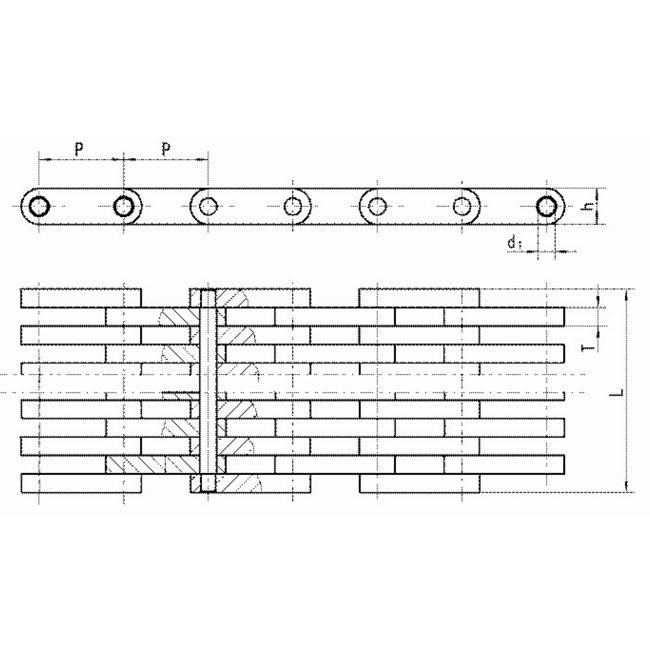

Key Product Parameters of Engineering Chains

Our engineering chains are manufactured to the highest standards, incorporating advanced materials and rigorous testing. Below is a detailed breakdown of their specifications:

Material Composition

- Alloy Steel: High-carbon content for superior strength and wear resistance.

- Stainless Steel: Corrosion-resistant ideal for food processing or marine environments.

- Heat-Treated Components: Enhanced hardness and durability through processes like quenching and tempering.

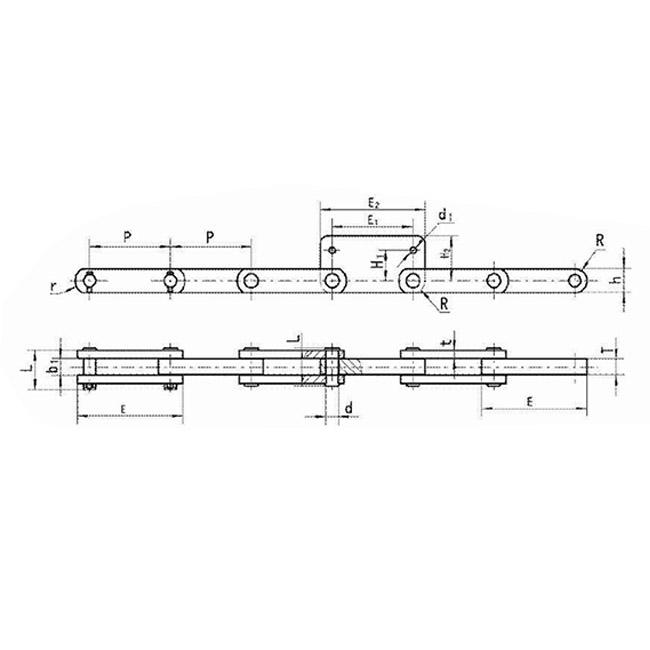

Dimensions and Tolerances

| Parameter | Specification Range | Unit |

|---|---|---|

| Pitch Size | 0.5 - 4.0 | inches |

| Breaking Load | 5,000 - 50,000 | pounds |

| Operating Temperature | -40 to 500 | °F |

| Weight per Foot | 0.8 - 12.5 | pounds |

Performance Metrics

- Tensile Strength: Up to 100,000 psi, ensuring minimal elongation under load.

- Fatigue Life: Exceeds 1 million cycles at rated capacity, based on ISO 606 standards.

- Lubrication Requirements: Self-lubricating options available; standard chains need periodic oiling.

Applications of Engineering Chains

Engineering chains are versatile and used across multiple sectors:

- Manufacturing: Conveyor systems in automotive assembly lines.

- Agriculture: Harvesting equipment and grain elevators.

- Mining: Heavy-duty chains for material handling in extreme conditions.

- Logistics: Sorting and packaging machinery in warehouses.

Frequently Asked Questions (FAQ) About Engineering Chains

What is the typical lifespan of an engineering chain?

The lifespan depends on usage conditions, but with proper maintenance, our chains can last 5-10 years in moderate environments. Regular lubrication and inspection are key to maximizing longevity.

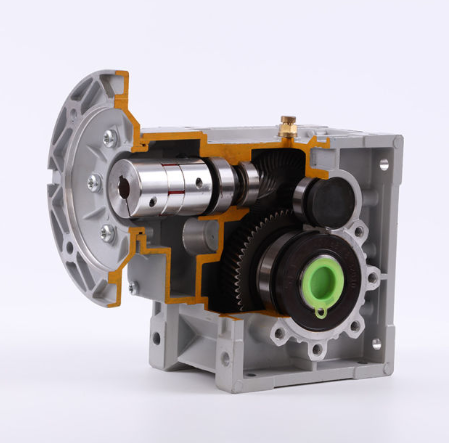

How do I select the right engineering chain for my application?

Consider factors like load capacity, environment (e.g., corrosive or high-temperature), and speed. Our product catalog includes selection guides, and we recommend consulting with our engineers for custom solutions.

Are engineering chains compatible with international standards?

Yes, our chains comply with ISO 606, ANSI B29.1, and other global standards, ensuring interoperability and safety in diverse industrial setups.

What maintenance practices are recommended for engineering chains?

Implement a routine check for wear, misalignment, and lubrication. Use high-quality lubricants and replace chains if elongation exceeds 3% of the original length to prevent failures.

Can engineering chains be used in high-temperature applications?

Absolutely. Our heat-resistant variants made from special alloys operate efficiently up to 500°F, with custom options available for even higher temperatures upon request.

Do you offer custom-sized engineering chains?

Yes, we provide bespoke manufacturing based on client specifications, including unique pitches, materials, and attachments to meet specific operational needs.