Chains are engineered for heavy-duty industrial applications, designed with superior tensile strength and corrosion resistance. Our product line encompasses various types, including roller chains, conveyor chains, and specialty chains, each tailored to specific operational demands. Built to withstand extreme conditions, these chains ensure longevity and reliability in sectors such as manufacturing, logistics, and automotive industries. With rigorous quality control and adherence to international standards, our chains deliver optimal performance, reducing downtime and maintenance costs for businesses worldwide.

Below is a comprehensive breakdown of the key specifications for our standard roller chains, which serve as the foundation of our product range. These parameters are critical for selecting the right chain for your application, ensuring compatibility and efficiency.

| Parameter | Value Range | Unit |

|---|---|---|

| Pitch (distance between pins) | 0.25 - 3.0 | inches |

| Inner Width | 0.15 - 1.5 | inches |

| Roller Diameter | 0.2 - 2.5 | inches |

| Breaking Load | 500 - 20,000 | pounds |

| Weight per Foot | 0.1 - 10.0 | pounds |

What types of chains are available for different industries?

We offer a diverse range, including roller chains for power transmission, conveyor chains for material handling, leaf chains for lifting applications, and specialty chains like silent chains for noise-sensitive environments. Each type is customized with specific materials and dimensions to meet industry standards such as ANSI or ISO.

How do I determine the correct chain size for my machinery?

To select the proper chain size, consider factors like load capacity, speed, and environmental conditions. Refer to the pitch and breaking load specifications in our tables; for instance, a #40 roller chain with a 0.5-inch pitch and 3,700-pound breaking load is suitable for moderate industrial use. Always consult our sizing guide or contact support for personalized recommendations based on your equipment's manual.

What maintenance is required to prolong chain life?

Regular maintenance includes cleaning to remove debris, lubricating with appropriate oils or greases every 100-500 operating hours, and inspecting for wear signs such as elongation or rust. For chains in harsh conditions, increase lubrication frequency and consider protective coatings. Our products come with maintenance schedules tailored to usage intensity.

Are these chains compatible with international standards?

Yes, our chains comply with major international standards like ANSI (American National Standards Institute) for dimensions and ISO (International Organization for Standardization) for quality and safety. For example, ANSI B29.1 standards govern roller chains, ensuring interoperability with global machinery parts.

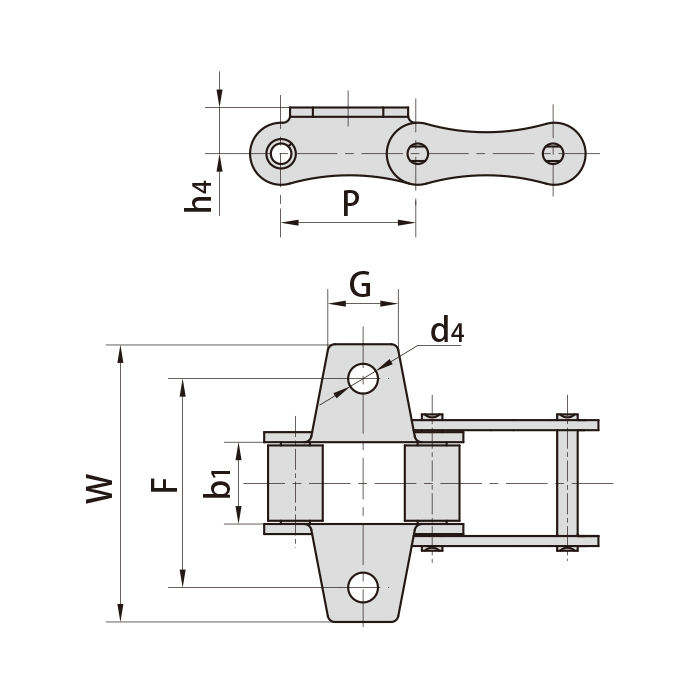

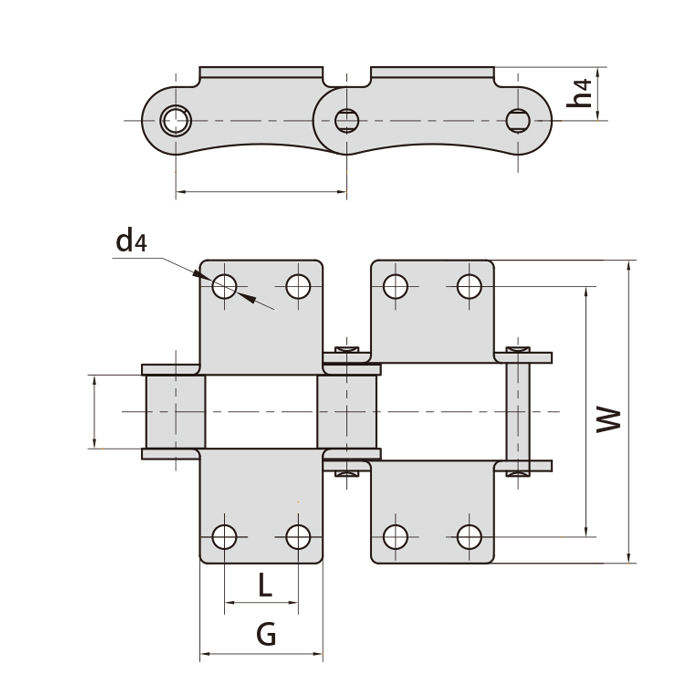

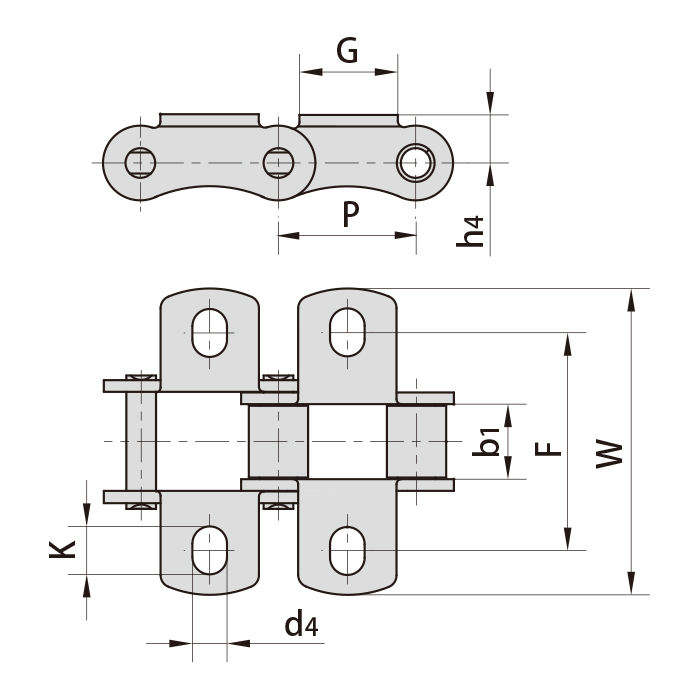

Can chains be customized for specific applications?

Absolutely, we provide customization options for length, material, and special features like attachments or coatings. Provide details such as operating load, temperature range, and environmental factors, and our engineering team will tailor a solution, such as a stainless steel chain with extended pitch for high-temperature conveyors.

What is the average lifespan of these chains under normal conditions?

Under normal operating conditions with proper maintenance, our standard chains last between 5,000 to 10,000 hours. Factors like load intensity, speed, and environment affect longevity; for instance, chains in abrasive environments may require replacement sooner, but our high-wear models can exceed 15,000 hours with optimal care.

How do I handle installation and tensioning?

Installation involves aligning sprockets properly, ensuring the chain is not over-tensioned to avoid excessive wear. Use a tension gauge to maintain the recommended slack, typically 2-4% of the chain length. Follow our step-by-step installation guide, which includes torque specifications for connecting links to prevent failures.

What warranties and support are offered?

We provide a standard warranty of 1-2 years against manufacturing defects, covering parts replacement or repair. Additionally, our customer support team offers technical assistance for installation, troubleshooting, and maintenance advice, available via email or phone during business hours.