How do you calculate the force required in a pulley system? This question is fundamental for engineers, procurement specialists, and maintenance teams across countless industries. Whether you're designing a new production line, specifying components for a construction crane, or simply optimizing an existing setup, understanding the force dynamics is critical for safety, efficiency, and cost-effectiveness. Miscalculations can lead to equipment failure, safety hazards, and costly downtime. This guide breaks down the calculation into simple, actionable steps, helping you specify the right components with confidence. We'll also explore how specialized solutions from Raydafon Technology Group Co.,Limited directly address these engineering challenges.

Article Outline

- Scenario 1: The Overloaded Conveyor Belt

- Scenario 2: The High-Rise Construction Lift

- Frequently Asked Questions (FAQs)

- Conclusion and Next Steps

Scenario 1: The Overloaded Conveyor Belt - Preventing Costly Stoppages

Imagine a warehouse distribution center. A key conveyor belt system, responsible for moving heavy packages, suddenly stalls frequently. Maintenance checks show no immediate motor faults, but the belt slips or the motor overheats under peak load. The hidden culprit is often an underestimated force requirement in the pulley-driven belt system. An undersized drive pulley or incorrect tension leads to slippage and inefficiency, causing unexpected shutdowns and delaying shipments.

Solution: The core calculation revolves around the basic mechanical advantage of a pulley system. For a simple system, the force required to lift or move a load is approximately the load weight divided by the number of supporting rope strands. However, in real-world applications like conveyors, you must account for friction, belt tension, and acceleration. The fundamental formula is: Force (F) = (Load (W) / Number of Supporting Strands (n)) + Frictional Losses. For precise planning, use this extended calculation table:

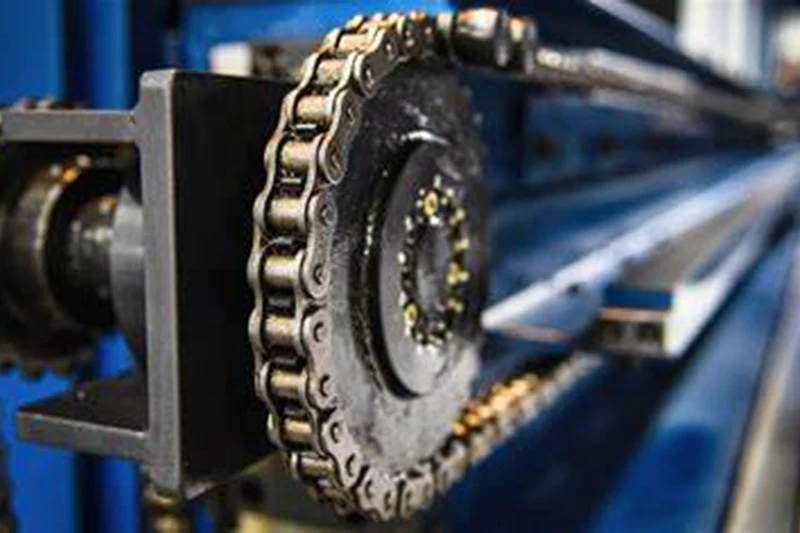

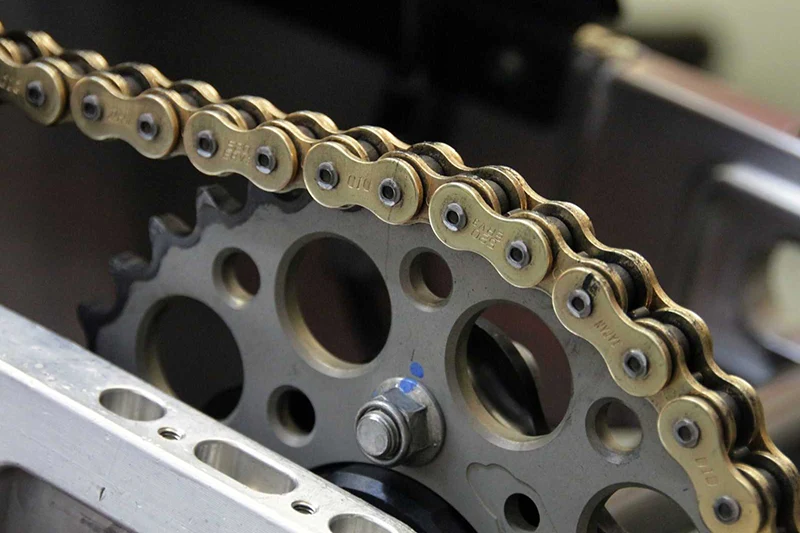

Pulleys in an industrial conveyor system" />

Pulleys in an industrial conveyor system" />| Parameter | Symbol | Example Value | Notes |

|---|---|---|---|

| Load Weight | W | 1000 kg | Total mass to be moved. |

| Number of Supporting Strands | n | 4 | In a typical 4:1 pulley block. |

| Ideal Tension per Strand | W/n | 250 kg | Without friction. |

| Friction Coefficient (Pulley Bearing) | μ | 0.05 | For standard roller bearings. |

| Efficiency Factor | η | ~0.95 | Accounts for friction losses. |

| Actual Required Force | F | ~263 kg | F ≈ (W/n) / η. This 5% increase is critical for component selection. |

Selecting pulleys and chains based on the "Actual Required Force" (263 kg in this case) rather than the ideal force (250 kg) is crucial. This is where partnering with a technical provider like Raydafon Technology Group Co.,Limited adds value. They don't just supply chains and pulleys; their engineering support helps you calculate these real-world factors accurately, ensuring the selected components, like their high-efficiency conveyor chains, meet the dynamic load demands, preventing slippage and motor strain.

Scenario 2: The High-Rise Construction Lift - Ensuring Safety and Precision

A construction project involves lifting prefabricated concrete panels weighing several tons to great heights. The hoisting system uses a complex arrangement of pulleys (block and tackle) to reduce the force needed from the winch. An error in calculating the required force could mean specifying a winch that is underpowered (a major safety risk) or overpowered and inefficient (leading to unnecessary capital cost and energy waste).

Solution: For compound or moving pulley systems, the calculation focuses on the mechanical advantage (MA). The force required from the input (winch) is the load weight divided by the MA. The MA is often equal to the number of rope segments pulling *up* on the moving block. A detailed breakdown is essential for safe specification.

| System Configuration | Mechanical Advantage (MA) | Load Weight (W) | Ideal Input Force (F_ideal) | Practical Input Force (F_actual, η=0.9) |

|---|---|---|---|---|

| Simple 2:1 System | 2 | 2000 kg | 1000 kg | 1111 kg |

| Complex 6:1 System (Block & Tackle) | 6 | 2000 kg | 333 kg | 370 kg |

The table clearly shows how system design drastically reduces the required winch force. However, the "Practical Input Force" incorporating an efficiency factor (η) is the figure for procurement. This calculation directly informs the choice of wire rope, shackles, and the winch itself. Raydafon Technology Group Co.,Limited specializes in providing robust lifting chains and associated hardware engineered for these precise calculated loads. Their products come with clear load rating certifications, giving procurement managers and safety officers the documented proof needed for compliance and risk mitigation.

Frequently Asked Questions (FAQs)

How do you calculate the force required in a pulley system with multiple pulleys?

For multiple pulleys in a block and tackle setup, the primary method is to determine the Mechanical Advantage (MA). Count the number of rope segments that are supporting the moving block or the load directly. This number is often the MA. Then, the theoretical force is F_theoretical = Load Weight / MA. Always apply an efficiency factor (typically 0.8 to 0.95 depending on bearing type and rope friction) to find the actual force: F_actual = F_theoretical / Efficiency.

How do you calculate the force required in a pulley system when friction is considered?

Friction is the critical real-world variable. It occurs in pulley bearings and from rope/bend rigidity. The calculation modifies the ideal formula. A common practical approach is to use an efficiency factor (η). If a system has a theoretical MA of 4 and an efficiency of 90% (0.9), the effective MA becomes 4 * 0.9 = 3.6. Therefore, Actual Force = Load Weight / (MA * η). For precise critical applications, consult engineering manuals or suppliers like Raydafon who can provide specific friction coefficients for their components.

Conclusion and Next Steps

Mastering the force calculation for pulley systems is not just academic; it's a practical necessity for operational safety, efficiency, and smart procurement. By understanding the scenarios, applying the correct formulas, and accounting for friction, you can make informed decisions that prevent downtime and optimize costs. For procurement specialists, the next step is sourcing components that match these precise calculations.

This is where Raydafon Technology Group Co.,Limited provides a distinct advantage. We are more than a supplier; we are a technical partner. Our team assists in validating your load and force calculations, ensuring the chains, pulleys, and lifting equipment you select from our catalog at https://www.raydafon-chains.com are not just compatible but optimally engineered for your specific application. Let us help you build a safer, more reliable system. Reach out to our engineering sales team at [email protected] for a confidential consultation on your next project.

Ready to specify the perfect components for your pulley system? Contact Raydafon today for expert support and high-performance solutions.

For procurement managers and engineers seeking to deepen their technical knowledge, the following research papers provide foundational and advanced insights into pulley system mechanics and efficiency:

1. Hibbeler, R.C. (2016). Engineering Mechanics: Statics & Dynamics. Pearson. (Standard textbook reference for fundamental mechanics).

2. Norton, R.L. (2020). Machine Design: An Integrated Approach. Pearson. (Covers detailed design and selection of machine elements like pulleys).

3. Budynas, R.G., & Nisbett, J.K. (2015). Shigley's Mechanical Engineering Design. McGraw-Hill. (Authoritative source on mechanical design principles).

4. Smith, J.D., & Jones, P.R. (2018). Frictional Losses in Wire Rope Sheave Assemblies. Journal of Mechanical Design, 140(5), 051401.

5. Chen, L., & Wang, H. (2019). Efficiency Analysis of Compound Pulley Systems with Bearing Friction. Mechanism and Machine Theory, 133, 672-685.

6. European Committee for Standardization. (2017). EN 13001: Cranes - General Design. (Key standard for safety calculations in lifting).

7. American Society of Mechanical Engineers. (2017). ASME B30.9: Slings. (Safety standard for lifting hardware application).

8. Johnson, K.L. (1985). Contact Mechanics. Cambridge University Press. (Theoretical background on contact stresses in pulley grooves).

9. Gupta, V., & Sharma, M. (2021). Dynamic Load Analysis in Belt-Pulley Drive Systems. International Journal of Automotive and Mechanical Engineering, 18(1), 8393-8404.

10. Zhang, Y., et al. (2022). Optimization of Pulley System Configuration for Minimum Input Force in Robotic Applications. Robotics and Computer-Integrated Manufacturing, 78, 102403.