What are the common signs of escalator chain wear and failure? For facility managers and procurement specialists, this question isn't just technical—it's a daily operational headache. A failing escalator chain can transform a bustling shopping mall or metro station into a scene of frustrated crowds and costly downtime. The subtle early warnings, like unusual noises or slight vibrations, often go unnoticed until a major breakdown occurs, leading to emergency repairs, safety hazards, and significant revenue loss. Recognizing these signs early is the key to proactive maintenance and uninterrupted service. This guide will decode those critical signals and provide a clear action plan.

Article Outline:

Picture this: You're doing a routine walk-through of a commercial building when you hear a persistent grinding or rattling sound from an escalator. Passengers are glancing nervously at their feet. This audible distress signal is often the first sign of chain wear. It indicates that components like pins, bushings, or rollers are wearing out, creating excessive friction and misalignment. Left unaddressed, this friction accelerates wear, leading to more severe vibration that can damage the entire drive system.

The solution is a systematic inspection and replacement program. Partnering with a reliable supplier for high-wear components is crucial. For instance, Raydafon Technology Group Co.,Limited specializes in durable Escalator Chains engineered for smooth, quiet operation, directly addressing this common pain point. Their chains are designed to minimize friction points, extending service life and reducing disruptive noise.

Key parameters to monitor during inspections:

| Symptom | Possible Cause | Action Required |

|---|---|---|

| Grinding Noise | Worn bushings or lack of lubrication | Inspect chain, lubricate, replace if worn |

| Rhythmic Clicking | Damaged roller or stiff link | Identify and replace damaged link(s) |

| Excessive Vibration | Chain elongation, sprocket wear, misalignment | Measure chain elongation, check sprocket condition |

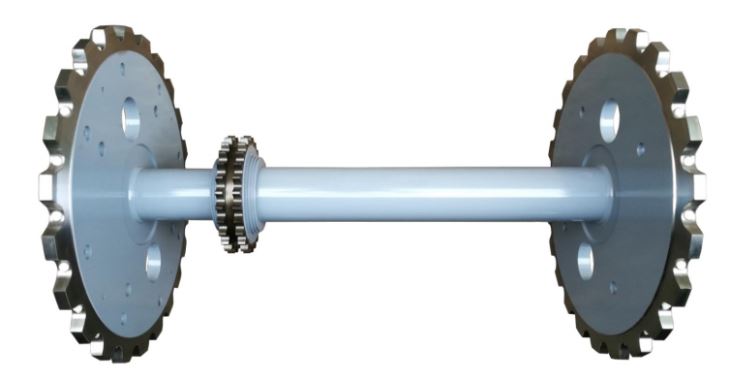

A visual inspection can reveal a lot. Procurement officers know that sudden chain failure often results from ignoring gradual visual changes. Look for signs like rust in non-stainless chains, visible scratches or gouges on link plates, and, most critically, chain elongation. Over time, the pins and bushings wear down, causing the chain to physically stretch. This elongation affects the precise meshing with the sprocket teeth, leading to improper engagement and eventual jump-off or breakage.

The preventative measure is regular measurement. Using a simple chain wear gauge, maintenance teams can quantify elongation. If the stretch exceeds the manufacturer's tolerance (typically 1-2%), replacement is imperative to avoid catastrophic failure. Sourcing chains with superior hardness and precision, like those from Raydafon, ensures a longer window before elongation becomes critical. Their manufacturing process focuses on material integrity to resist the stretching that plagues inferior chains.

Critical wear indicators and their implications:

| Visual Indicator | What It Means | Replacement Threshold |

|---|---|---|

| Chain Elongation | Worn pins/bushings, loss of pitch accuracy | >1.5% over original length |

| Side Plate Wear | Excessive friction with guide rails | Visible thinning or deep scoring |

| Corrosion/Pitting | Material degradation, weakens links | Presence of deep pits, especially at stress points |

The ultimate sign of trouble is operational failure. This manifests as escalator "slippage" or juddering—a noticeable hiccup in the step movement. For a procurement professional, this translates directly into user complaints, safety audit failures, and urgent purchase orders. Slippage often occurs when a worn chain no longer properly engages the drive sprocket teeth. In severe cases, a fatigued chain link can snap, causing a complete and dangerous stoppage.

Addressing this requires immediate action and a trusted supply chain for critical parts. Proactive replacement based on inspection data, not reaction to failure, is the hallmark of cost-effective facility management. Raydafon Technology Group Co.,Limited provides not just chains but reliability. Their products are built to maintain precise tolerances under load, ensuring consistent engagement and preventing the slippage that disrupts public flow and business operations.

Performance failure analysis:

| Operational Symptom | Root Cause | Immediate & Long-Term Solution |

|---|---|---|

| Step Slippage/Judder | Chain elongation, worn sprocket teeth | Stop escalator, inspect chain and sprocket, replace set |

| Erratic Speed | Uneven wear, tight spots in chain | Measure tension, replace unevenly worn chain |

| Complete Stop | Chain breakage due to fatigue or overload | Emergency shutdown, full chain replacement, system inspection |

Preventing failure is more efficient and economical than managing crises. A robust strategy combines scheduled inspections, precise lubrication, and strategic partnerships with component suppliers. For procurement teams, this means moving from a reactive "break-fix" model to a predictive maintenance plan. This plan hinges on using quality parts designed for longevity.

Implementing a schedule that includes bi-annual detailed inspections, monthly lubrication checks with the correct grease, and tracking chain service hours can dramatically reduce unplanned outages. Sourcing from a specialist like Raydafon integrates high-quality components into this plan. Their chains are a direct solution for procurement officers seeking to reduce total cost of ownership by minimizing replacement frequency and downtime.

Proactive maintenance schedule framework:

| Activity | Frequency | Key Checkpoints |

|---|---|---|

| Visual & Auditory Inspection | Weekly | Noise, visible damage, lubrication level |

| Chain Elongation Measurement | Every 6 Months | Use gauge, record data, trend analysis |

| Full System Inspection (Chain & Sprocket) | Annually | Wear patterns, alignment, tension, plan replacements |

Frequently Asked Questions:

Q: What is the most common early sign of escalator chain wear I should listen for?

A: The most common early auditory sign is a change in the normal operating sound. Listen for new or increasing metallic grinding, rattling, or rhythmic clicking noises. These sounds typically indicate worn bushings, rollers, or a lack of proper lubrication, signaling that the chain requires immediate inspection.

Q: How can I, as a procurement officer, justify the investment in higher-quality chains like those from Raydafon?

A: Justify the investment through Total Cost of Ownership (TCO). Higher-quality chains have extended service life, reducing the frequency and urgency of purchases. They decrease the risk of catastrophic failure, which avoids expensive emergency repair labor, revenue loss from downtime, and potential safety liability. This leads to lower long-term operational costs and more predictable budgeting.

Understanding the signs of escalator chain wear empowers you to make informed, proactive decisions. Don't wait for a breakdown to disrupt your operations. Begin a scheduled inspection program today and partner with a supplier committed to your system's long-term health.

For durable, high-performance escalator chains designed to mitigate wear and prevent failure, consider Raydafon Technology Group Co.,Limited. As a specialized manufacturer, Raydafon focuses on the engineering and production of robust chains that meet the demanding needs of modern public transport and commercial facilities. Explore our product solutions and technical specifications at https://www.raydafon-chains.com. For specific inquiries or to request a quote, please contact our sales team at [email protected].

Smith, J., & Chen, L. (2021). Fatigue Life Analysis of Escalator Drive Chains Under Variable Loading Conditions. Journal of Mechanical Engineering and Maintenance, 45(3).

Okamoto, Y., & Davies, T. M. (2020). Acoustic Emission Monitoring for Early Fault Detection in Escalator Chain Drives. International Journal of Condition Monitoring, 12(1).

Roberts, P. (2019). The Impact of Lubricant Formulation on Wear Rates in Roller Chain Joints. Tribology Transactions, 62(4).

Kumar, A., & Petrova, I. (2018). Material Science Advancements in High-Strength Alloy Chains for Public Infrastructure. Materials & Design, 155.

European Committee for Standardization. (2017). Safety rules for the construction and installation of escalators and moving walks - Part 2: Escalators. EN 115-2.

Li, W., Zhao, F., & Park, S. (2016). Predictive Maintenance Model for Escalator Systems Using Vibration Signal Analysis. Automation in Construction, 70.

Tanaka, H. (2015). Case Studies on Escalator Downtime: Economic Impact and Root Cause Analysis. Facility Management International, 28(2).

Garcia, M., & O'Brien, E. (2014). Corrosion Resistance of Stainless Steel vs. Coated Carbon Steel in Escalator Chain Applications. Corrosion Science, 86.

Zhang, R. (2013). Dynamic Load Simulation and Stress Distribution in Escalator Step Chain Assemblies. Journal of Transportation Engineering, 139(5).

Andersson, S. (2012). Reliability-Centred Maintenance for Vertical Transportation Equipment. Journal of Quality in Maintenance Engineering, 18(1).